We have now successfully 3D printed stainless steel at the Makerspace!

We have printed stainless steel objects on our Ultimaker S5 3D printer. The filament used is a Product from BASF called Ultrafuse 17-4. It is a filament that contains actual stainless steel metal as well as a plastic used as a binder.

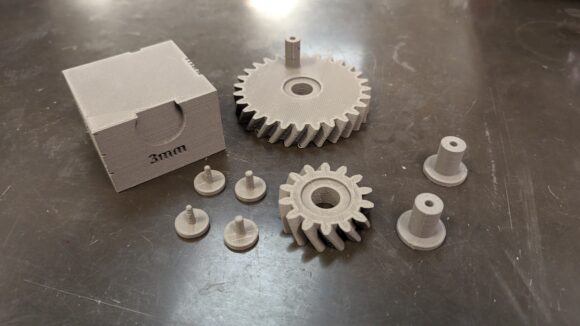

The filament was 3D printed on our Ultimaker S5 printer. The setup was slightly complicated involving scale different amounts in different directions as well as being very conscious of any overhangs and support areas. After printing, the “green” parts were then shipped to New York to be processed by a method called sintering. This removes all of the binder and all that is left is the stainless steel. The end result is a pure stainless metal object.

I wanted to come up with a project that was worthy of the process involved. I designed a base that contains two helical gears, with a handle to rotate them and a pin system to hold everything in place. Helical gears cannot be machined on our Tormach, and usually requires a 5 axis CBC mill.

The Parts & Process:

- Base – Aluminum T6060 – Machined both sides on the Tormach 3 axis CNC

- Pins – “Ultrafuse 17-4 “- 3D Printed on the S5

- Handle – Nylon – 3D Printed on the S5

- Helical Gears – “Ultrafuse 17-4 “- 3D Printed on the S5

More Information on our Makerspace Projects Gallery >