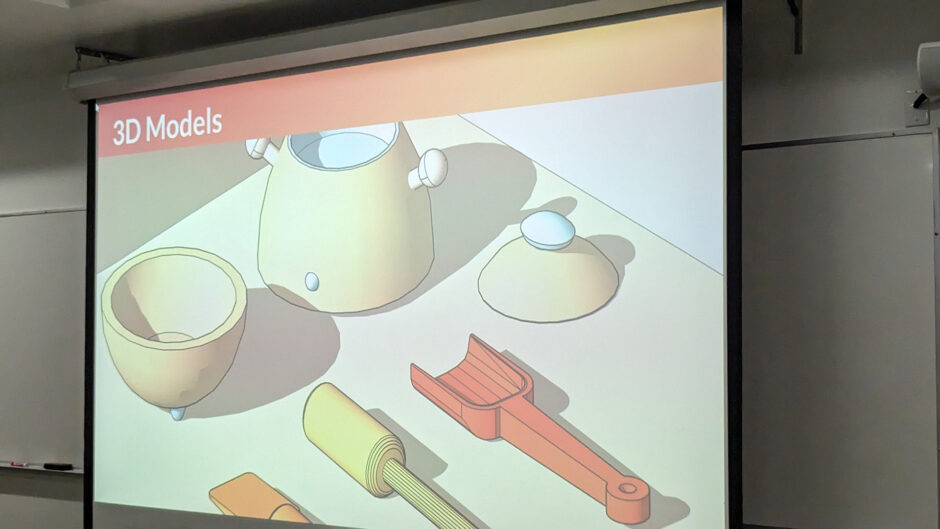

WMDD4905 3D Design

Class project presentations

This summer I attended the student presentations of Peter Vysek’s WMDD 4905 3D Design class. I was impressed with the level of concepts.

The design involved creating programs as well as objects for their concepts. All of the 3D objects were printed at the Makerspace.

Carnivale!

- María Alonso Villela

- Daniela Matheu

- María Martín Galván

- Natalia Cruz Cerecedo

- Joanna García

- Valentina Jaramillo

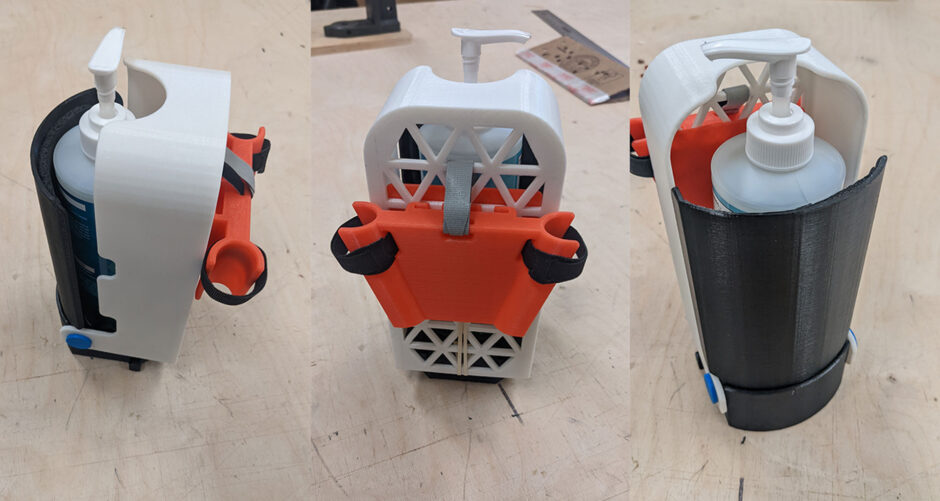

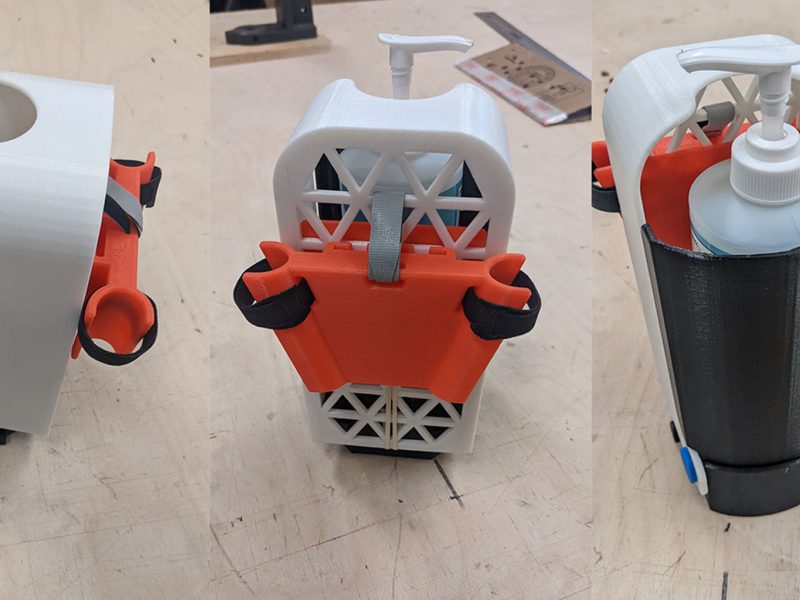

Engineering Student project

Engineering students created this design & prototype for a real world client. The design is a cup or bottle holder for a wheel chair. Unique to this design is the front piece is sprung and clamps the bottle/cup in place. The bottle can easily be taken out when needed. The students printed a second version using the Makerspace S5 Ultimaker in nylon for durability and strength. The end client is actually using it.

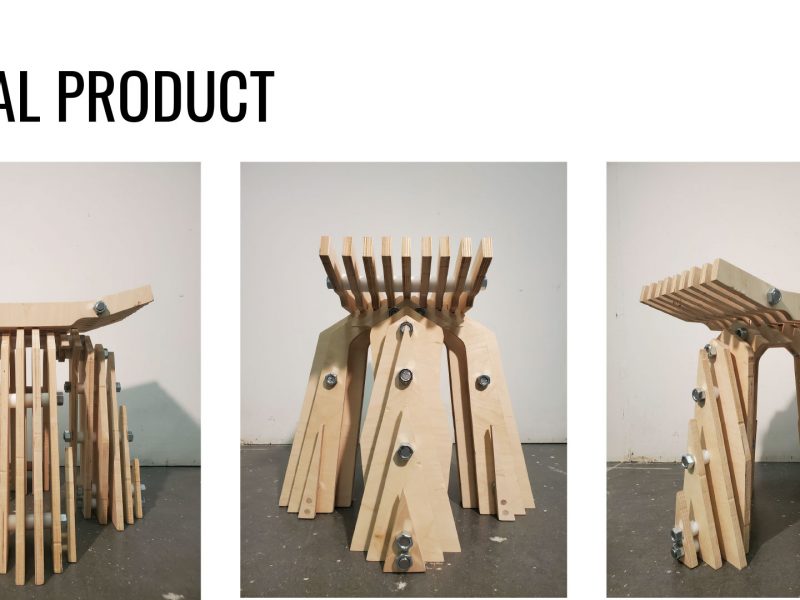

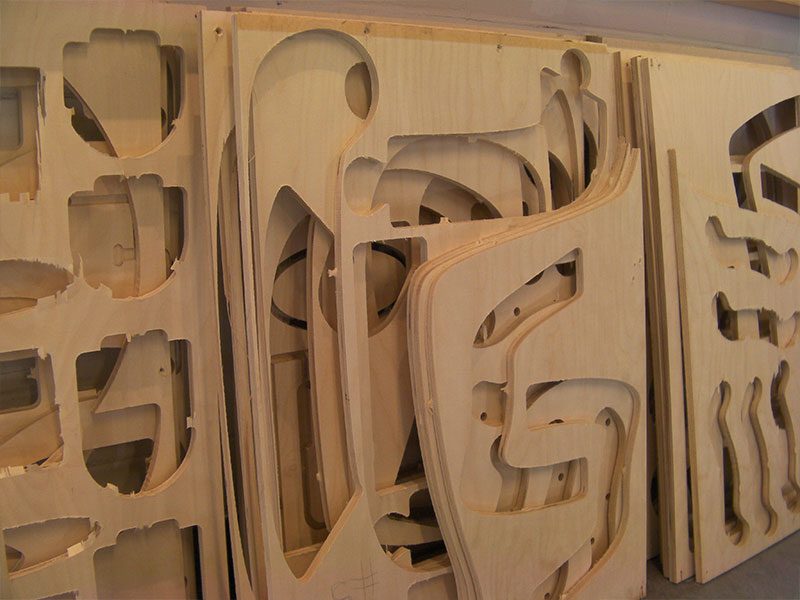

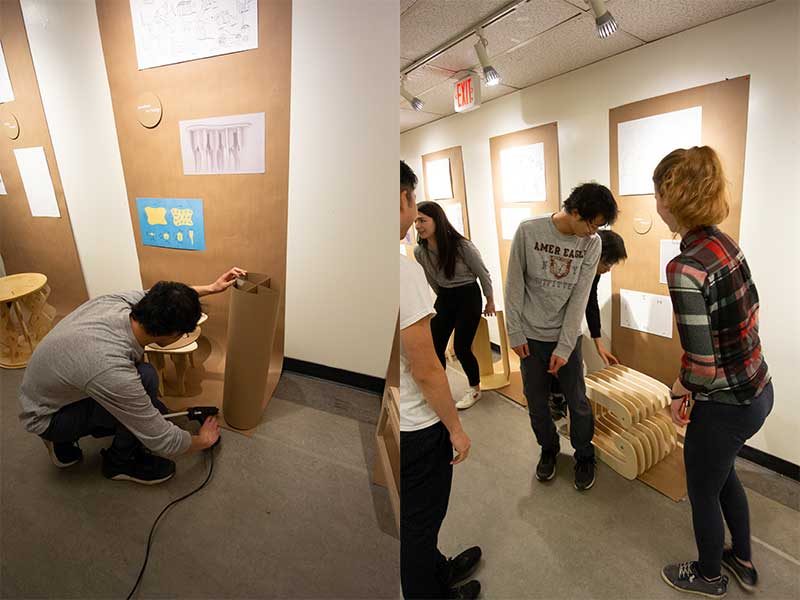

CNC STOOLS

Fine Arts 2021

Fine Arts Design instructor Philip Robbins gave his students this project to design a small, personal stool that efficiently utilized only one 5’X5′ piece of plywood, a single fabrication process, no external fasteners, and eco-friendly finishes.

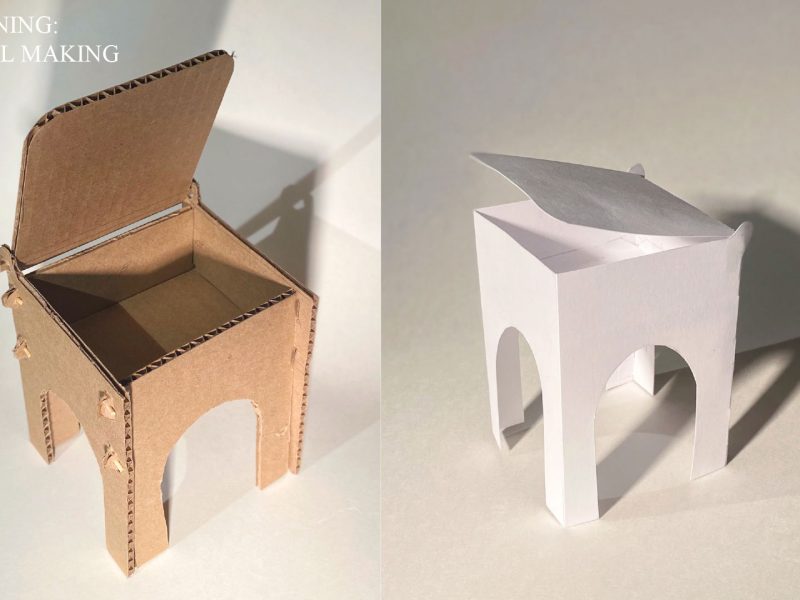

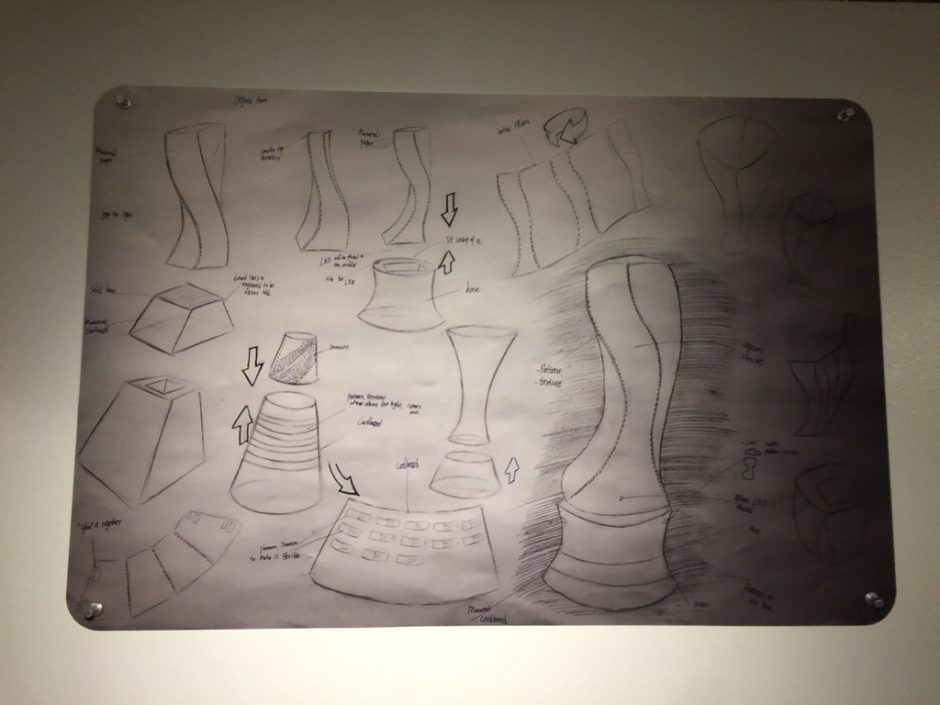

Students first started with ideation and iteration sketches, moving to the Rhino 3D modeling program to create an accurate digital form.

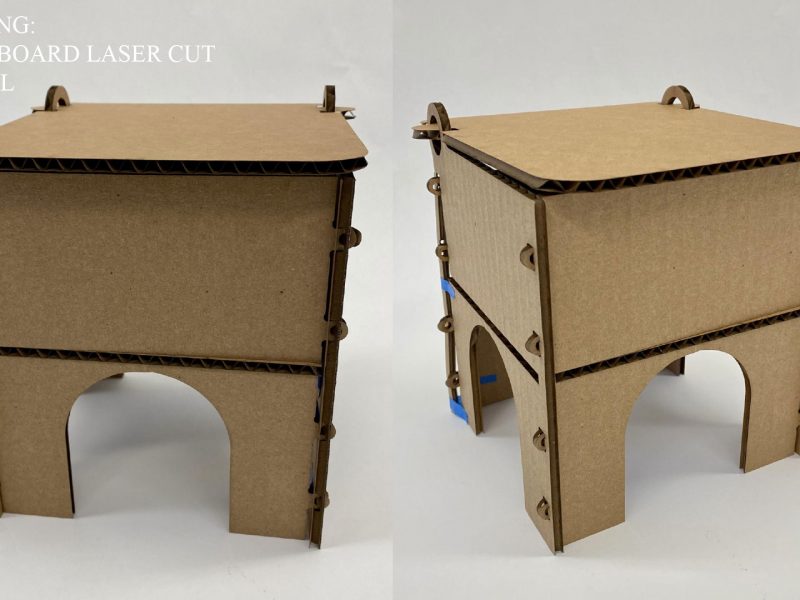

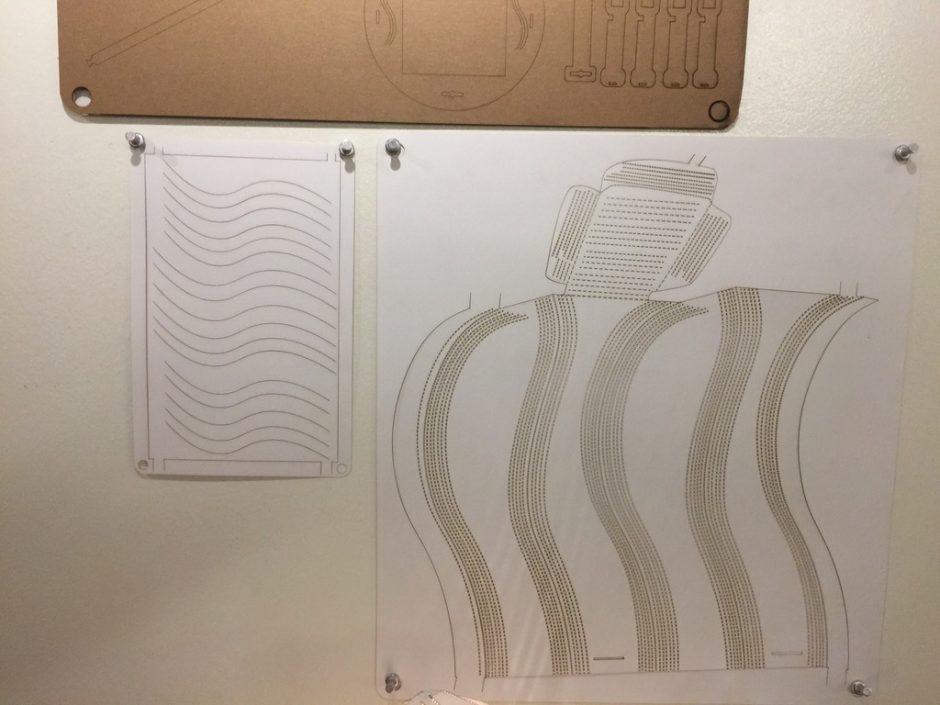

The students exported the Rhino files to Adobe Illustrator, using this file to laser cut an accurately scaled working prototype.

Once they were happy with the cardboard mockups, students then exported their files to Vcarve to create the CNC router toolpaths. This file was then configured to run on our Romaxx CNC machines, the plywood was CNC cut, parts were cleaned up then carefully assembled and finished.

Gallery of all of the chairs as well as person student presentations are below.

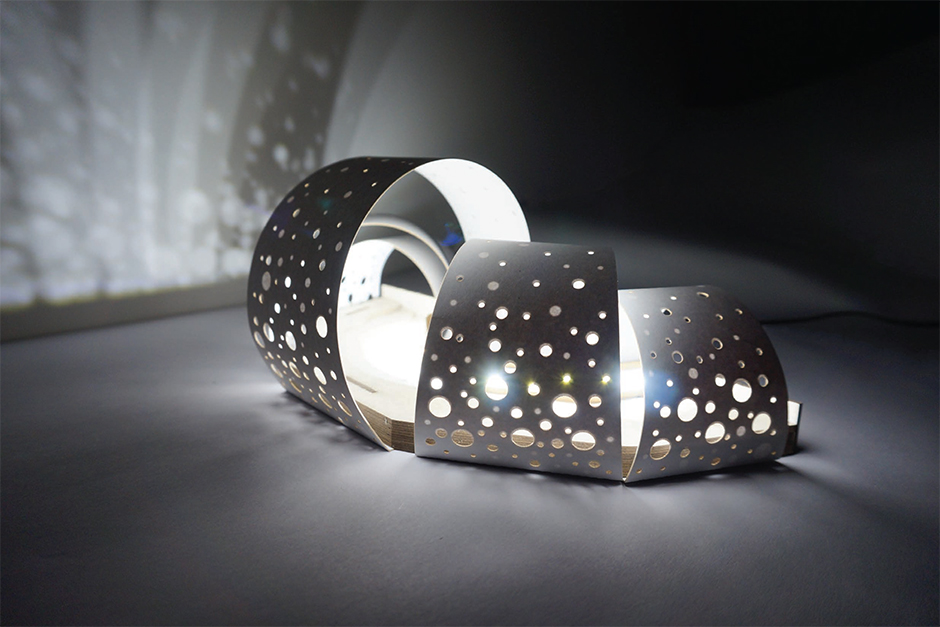

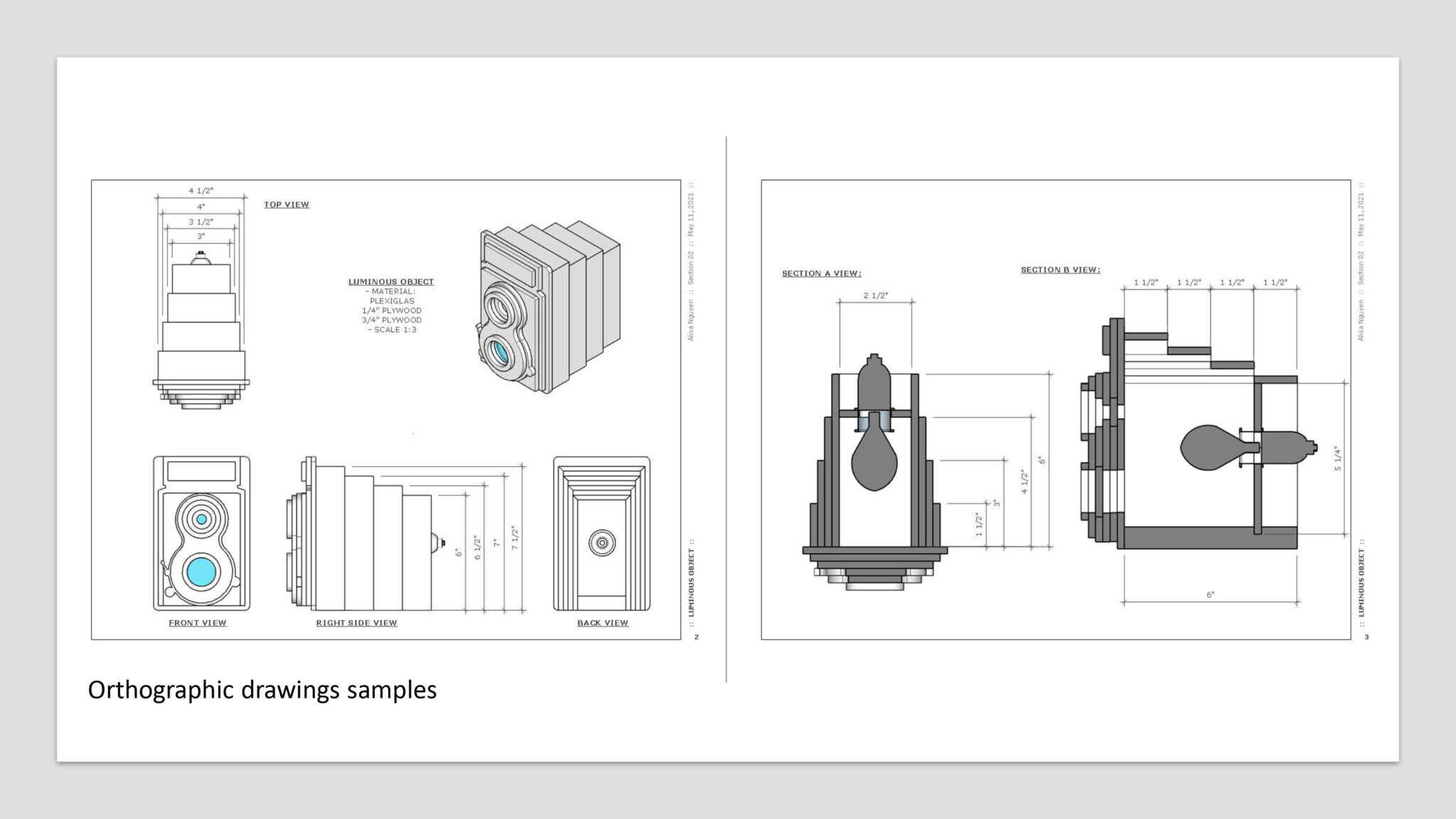

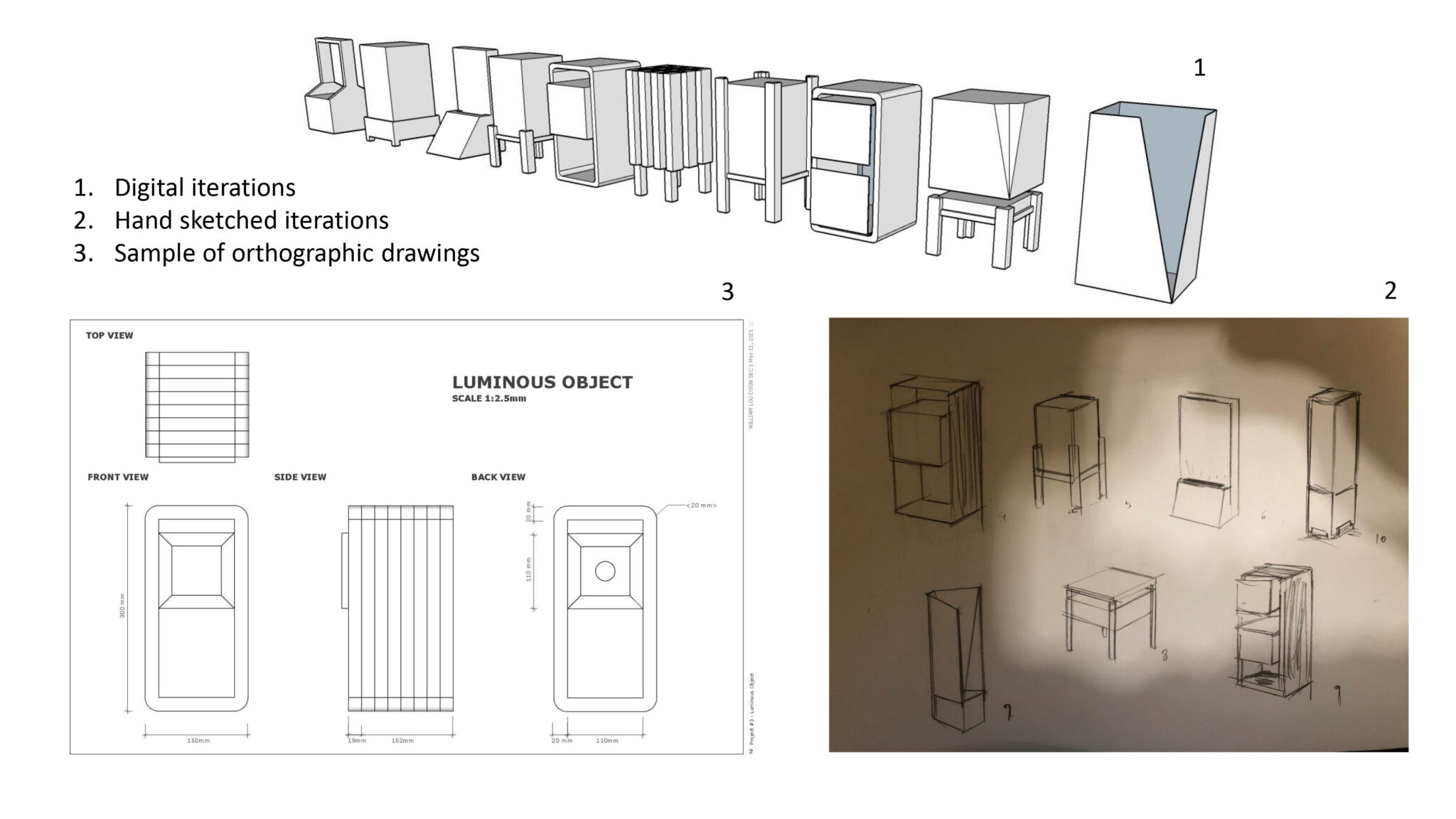

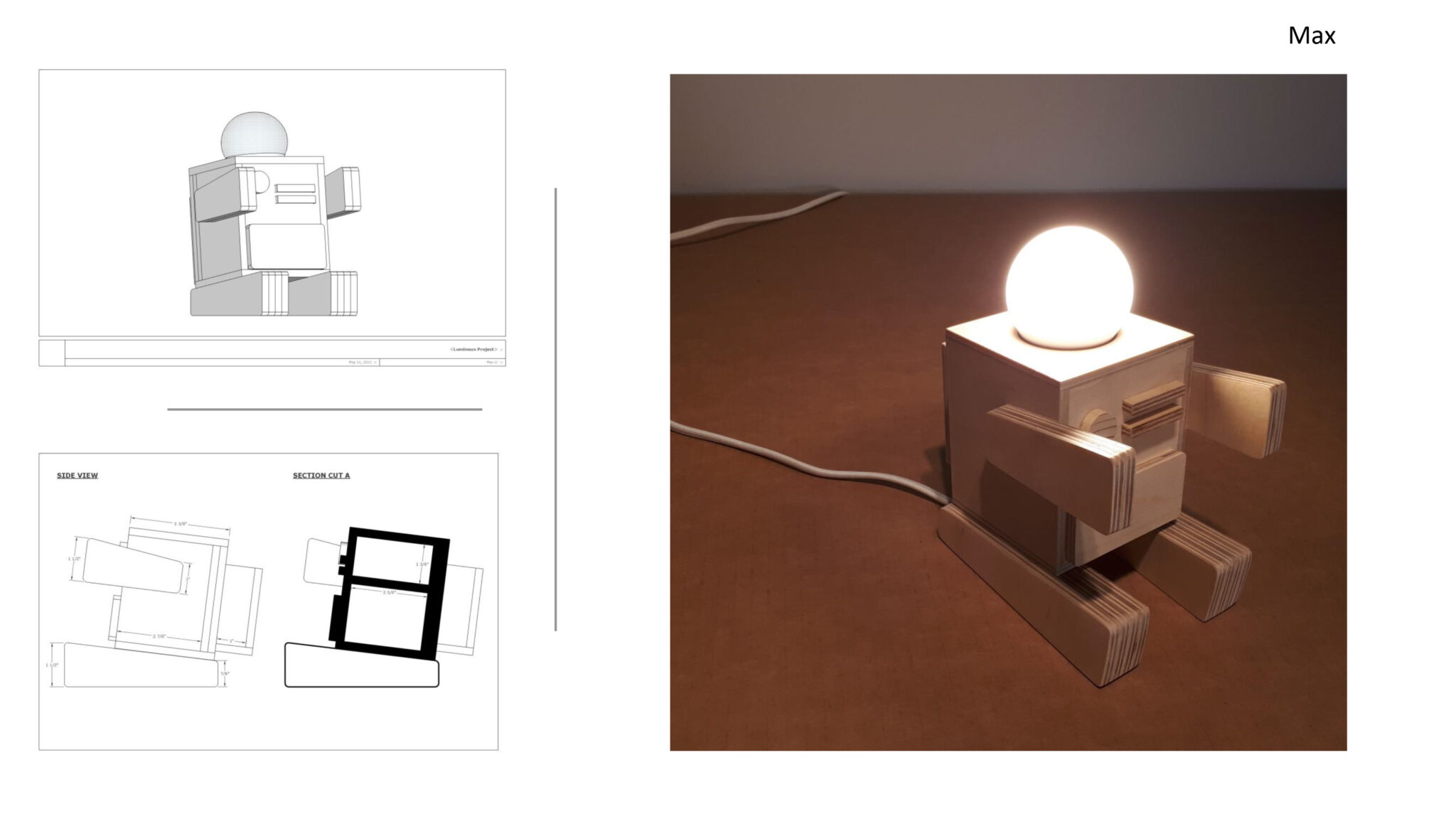

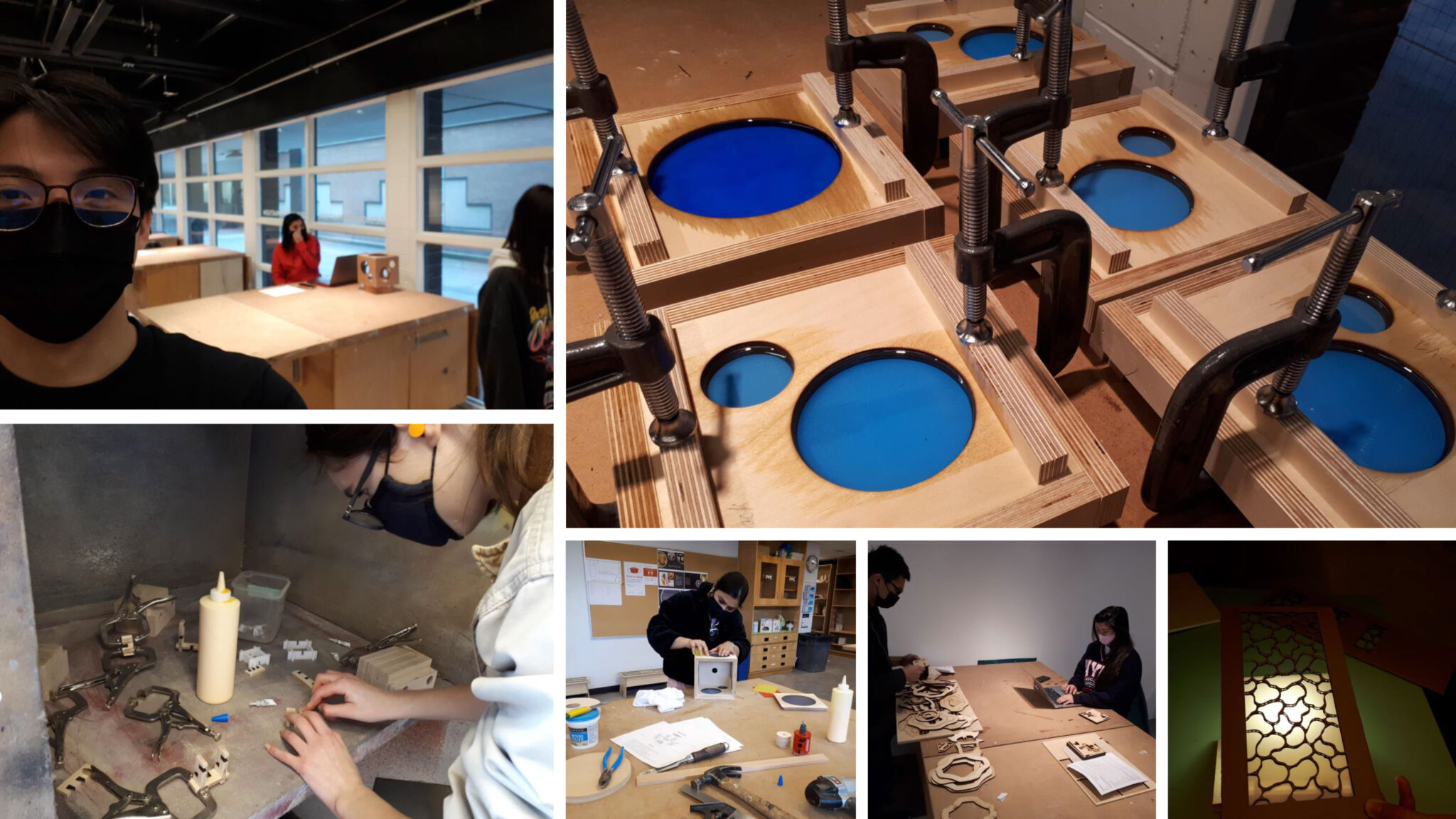

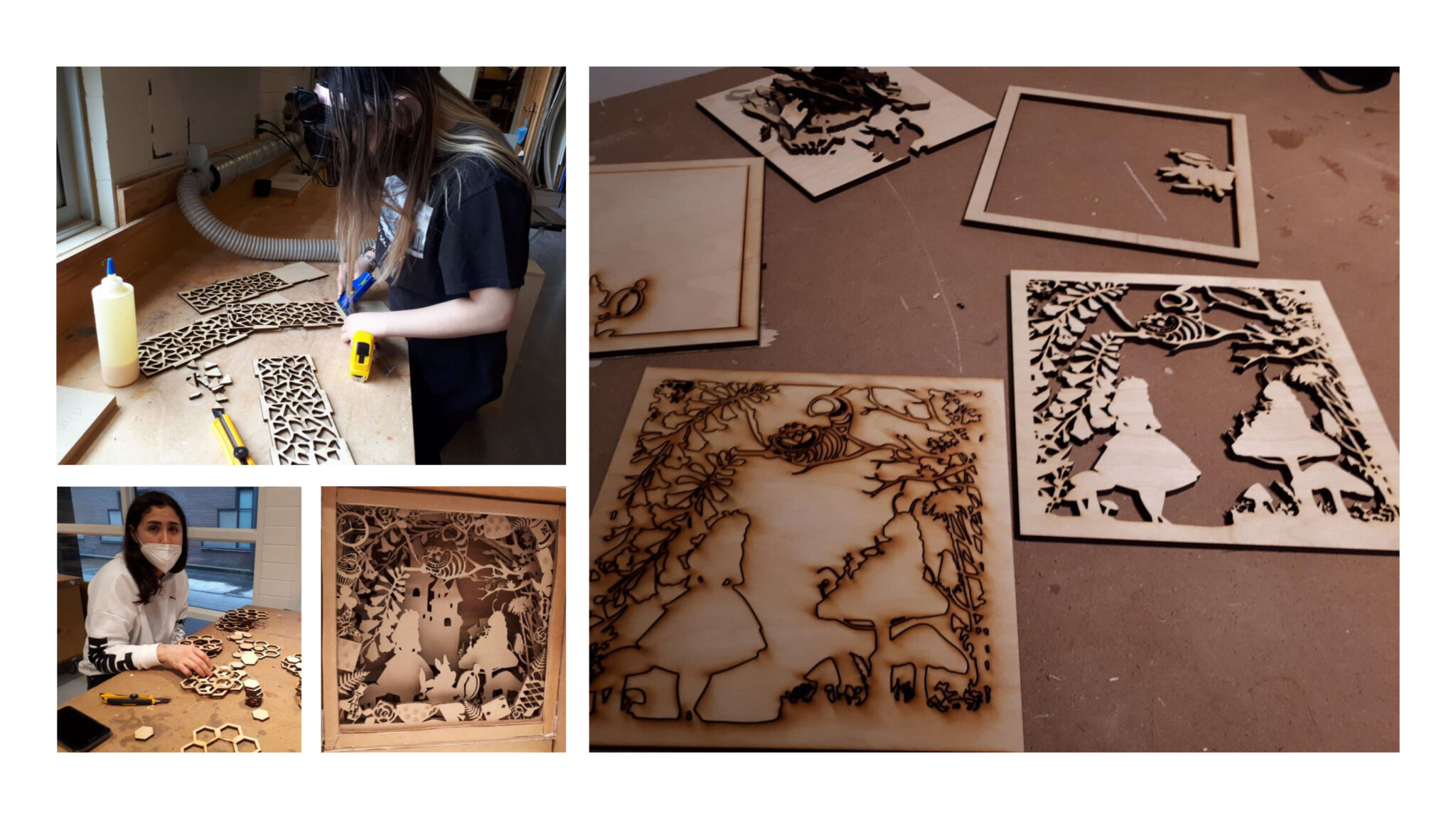

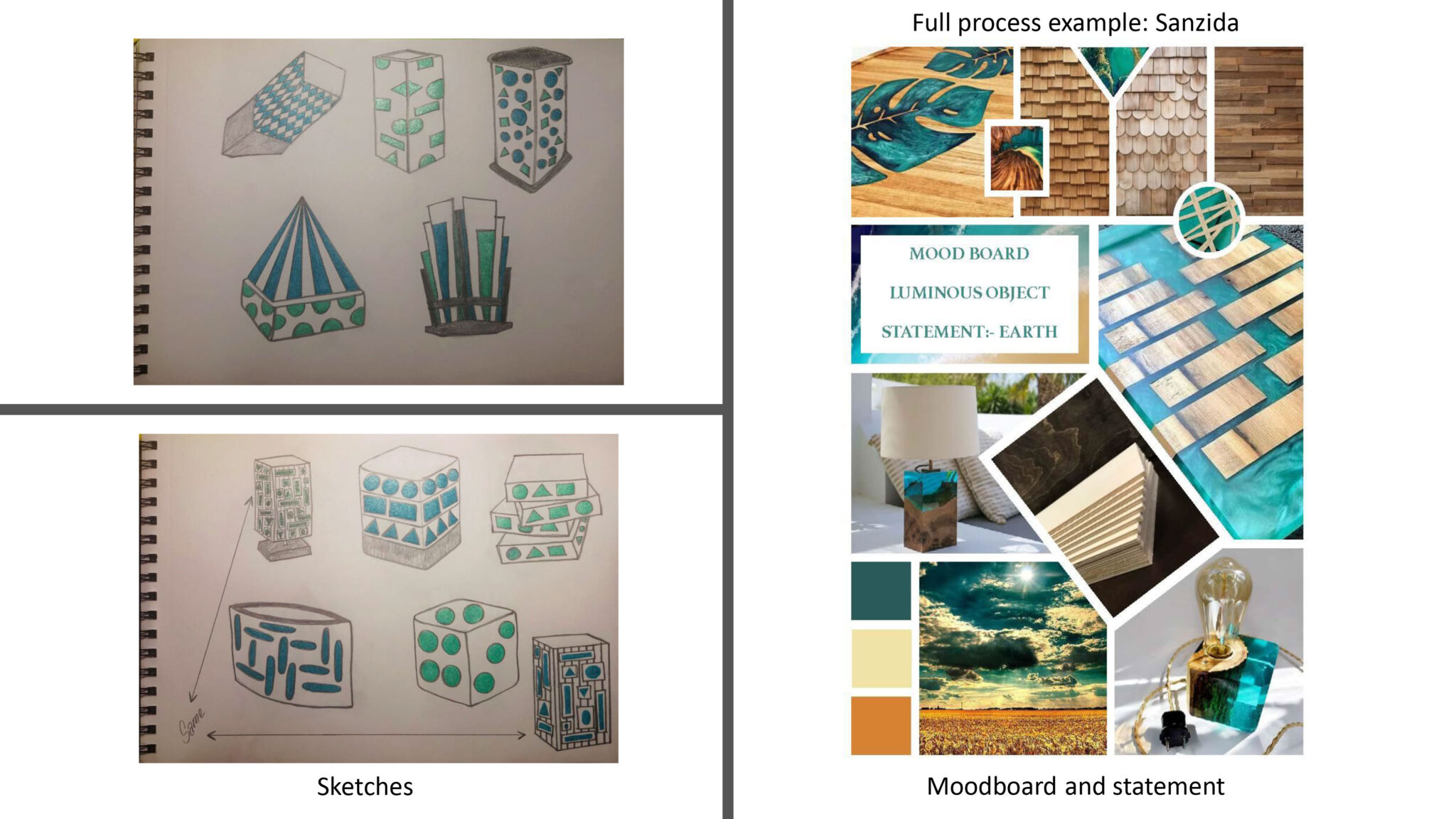

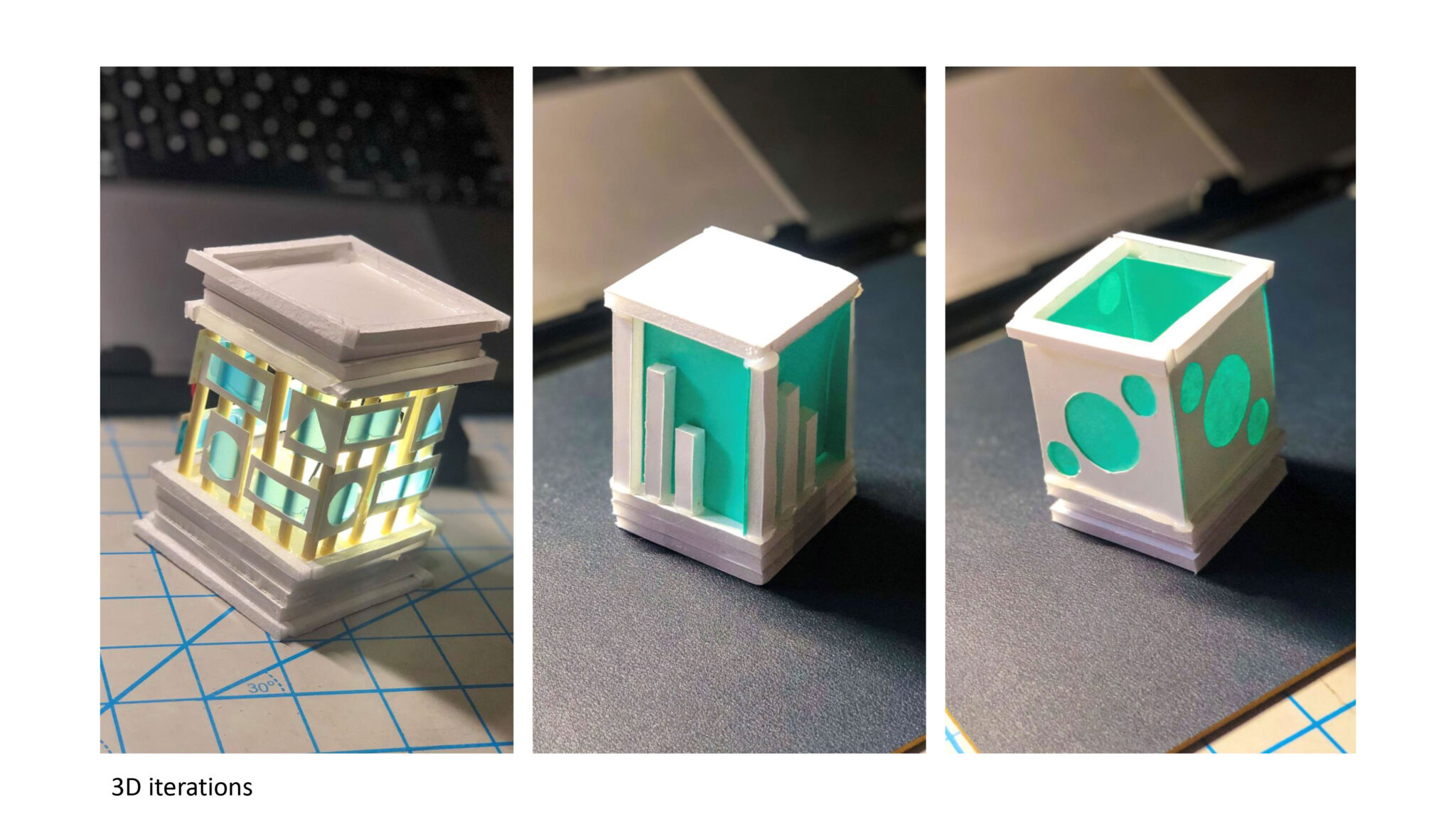

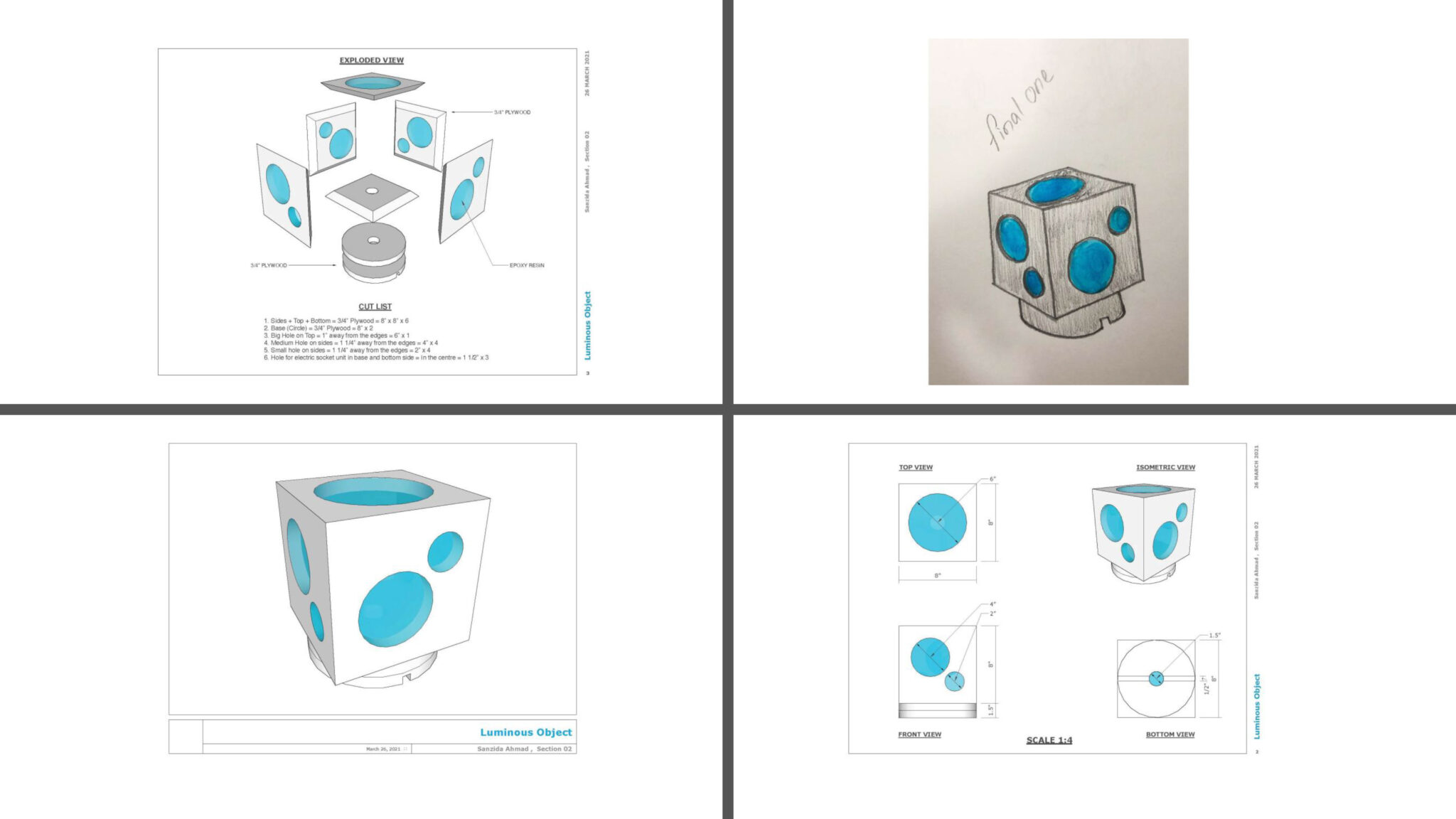

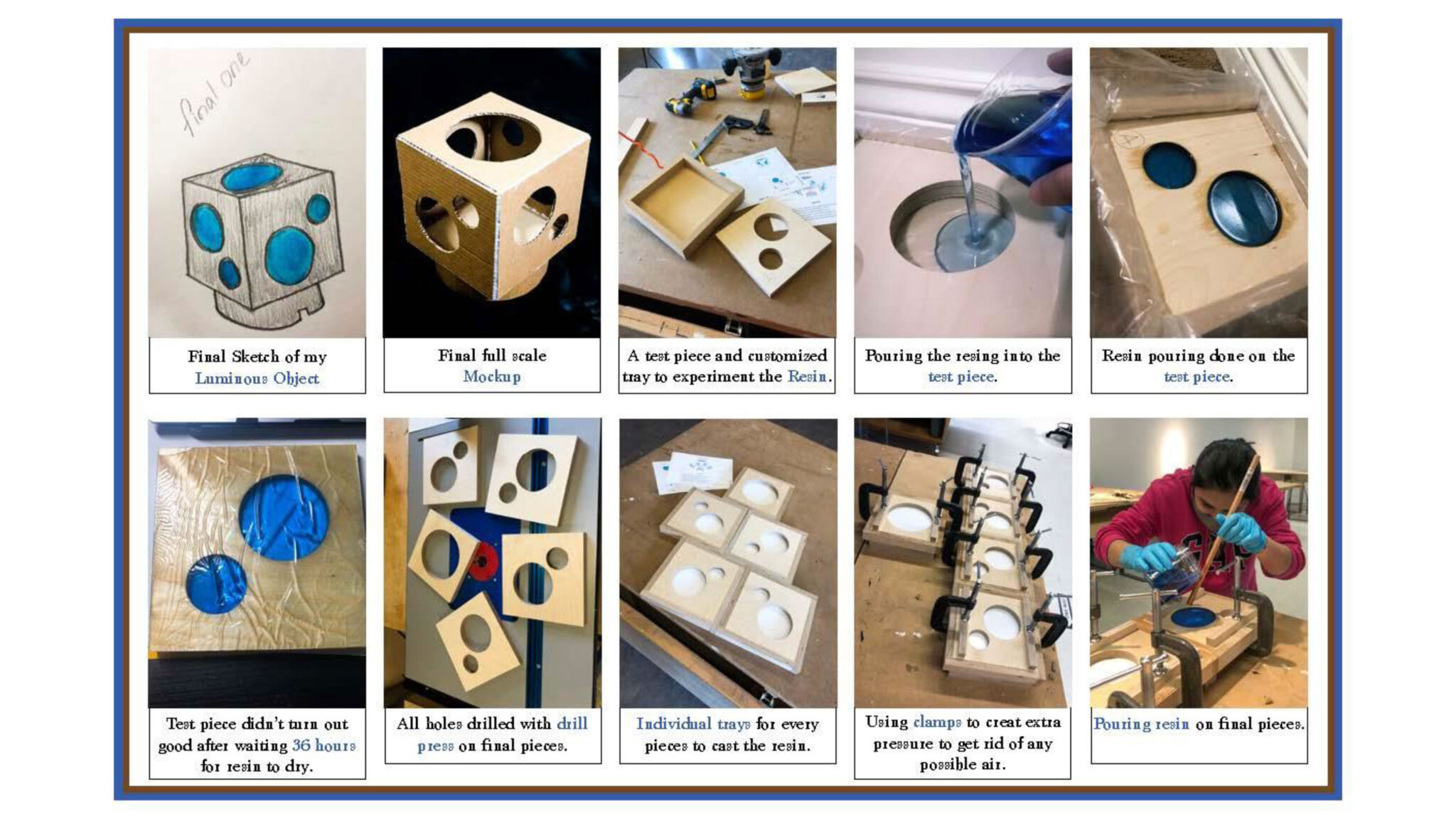

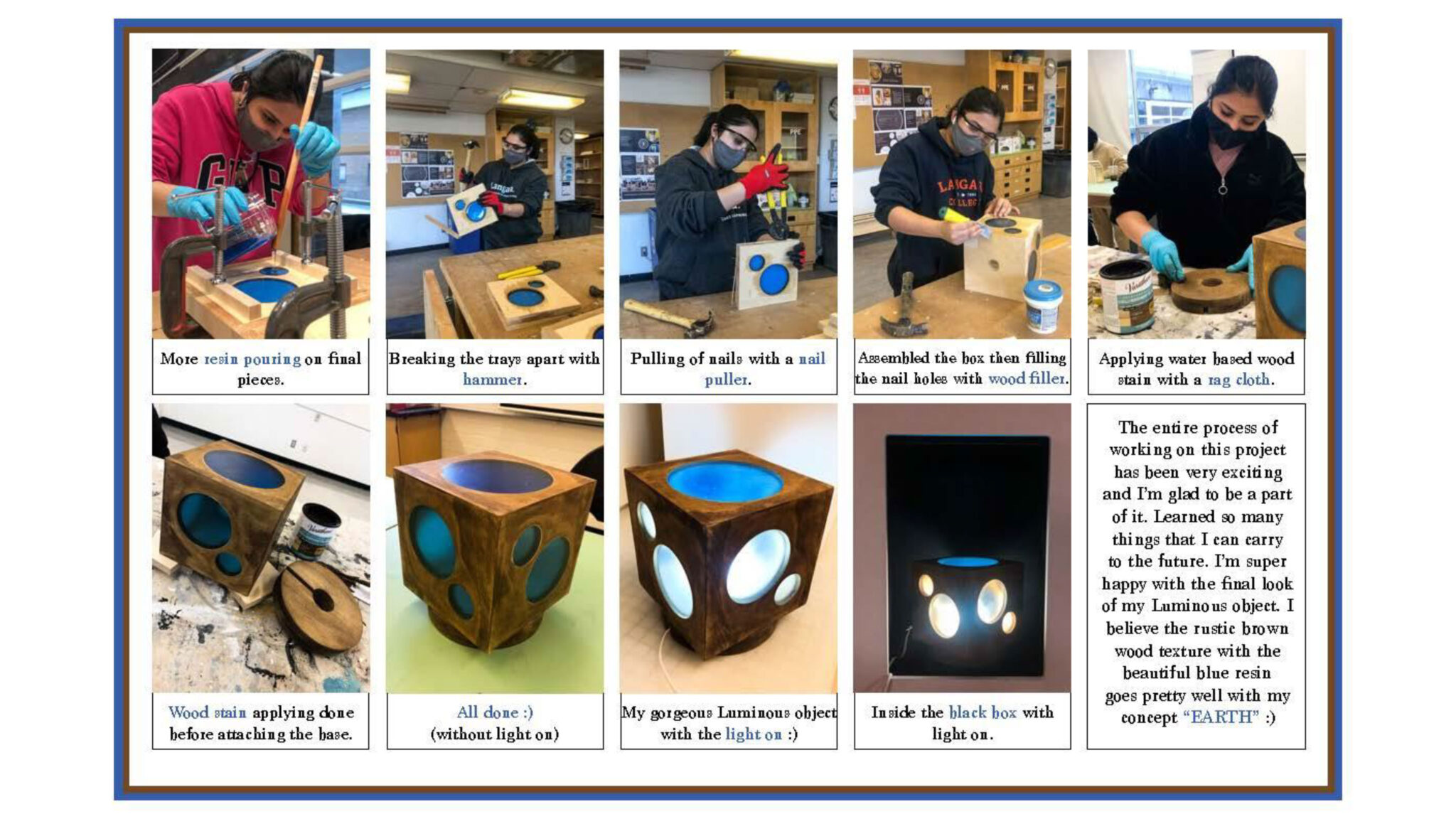

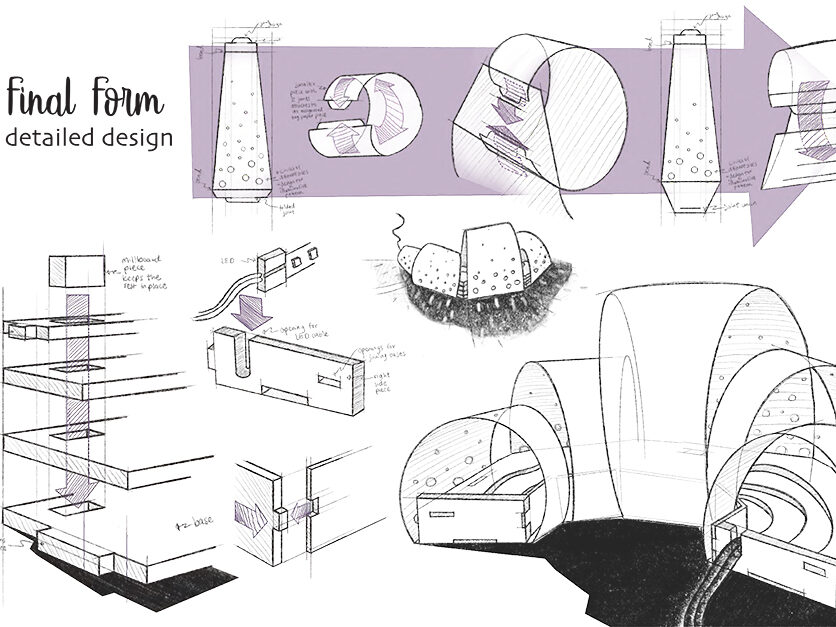

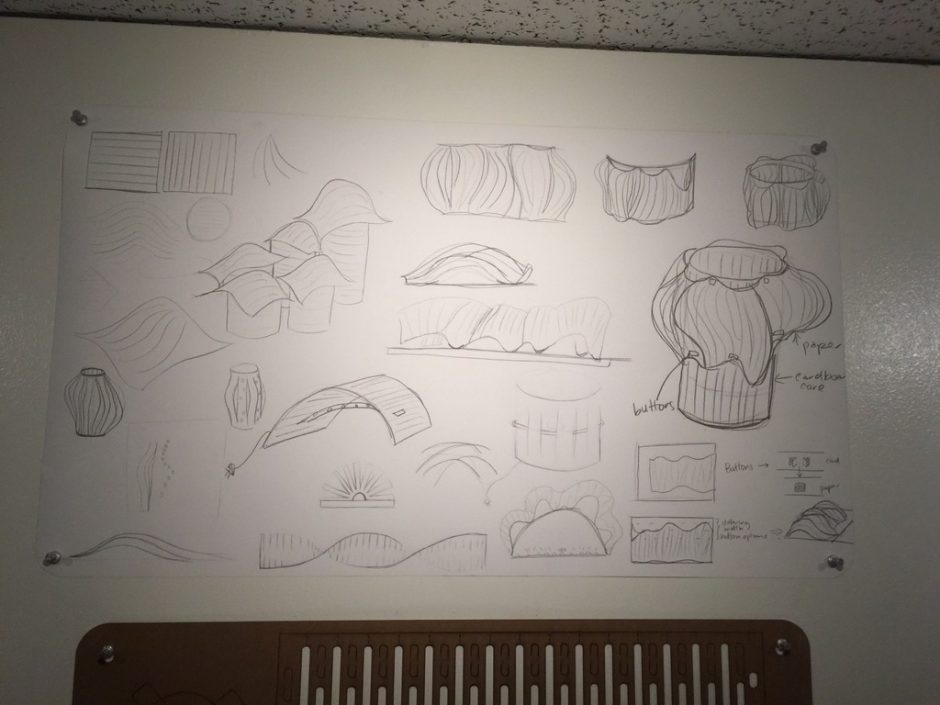

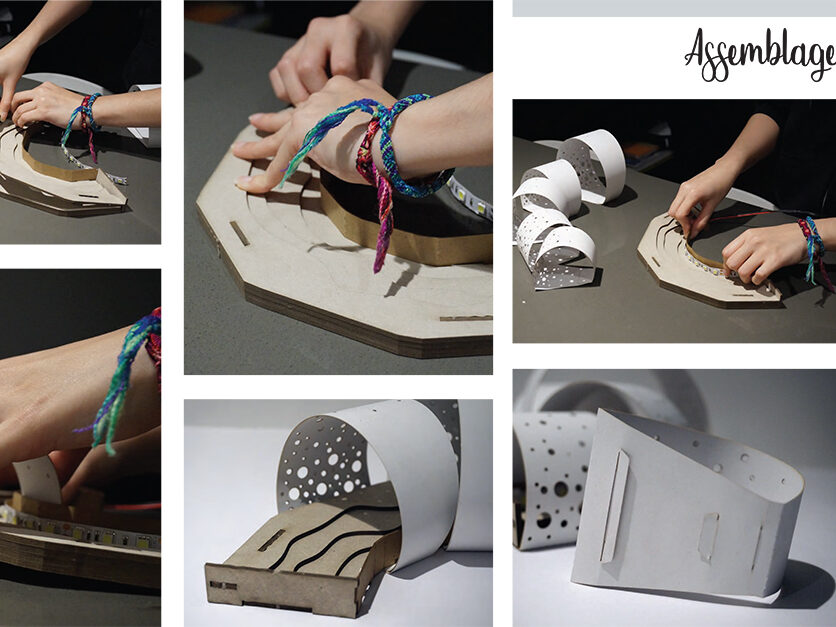

LUMINOUS OBJECT

Design Formation 2021

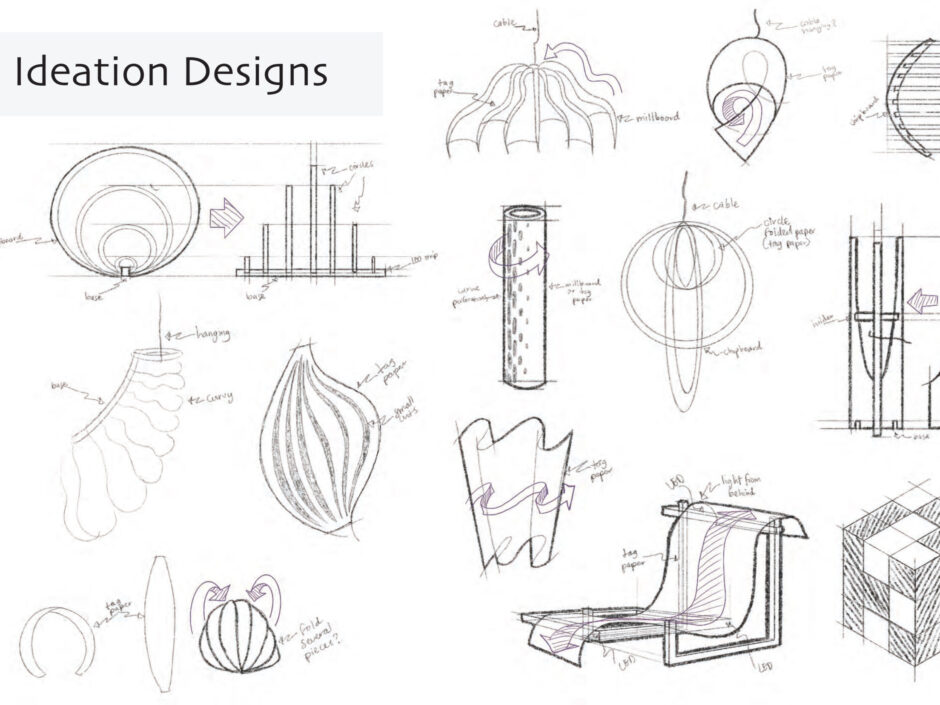

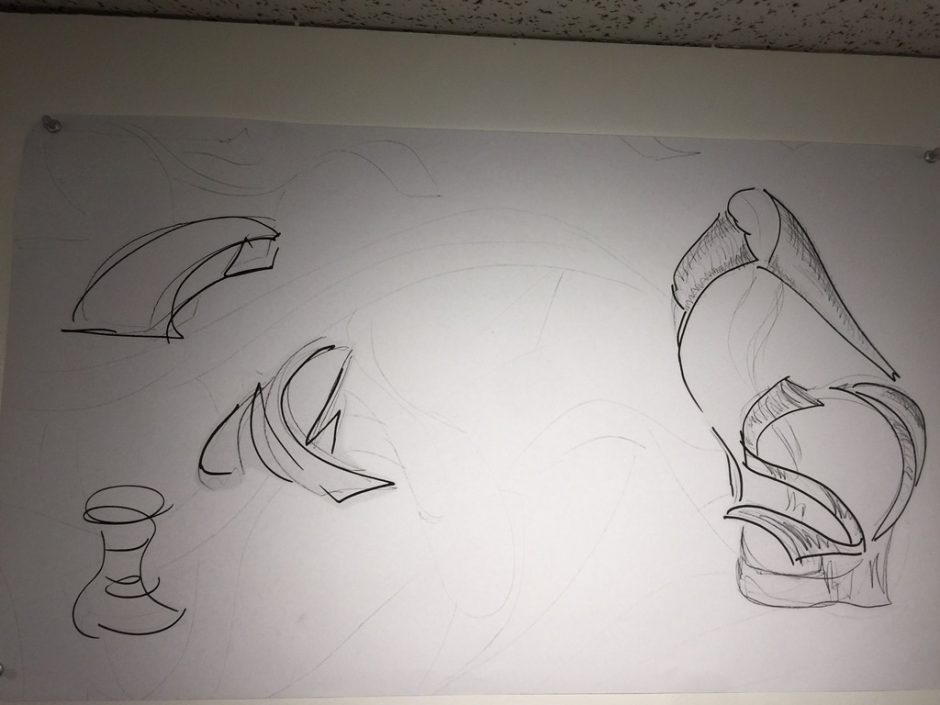

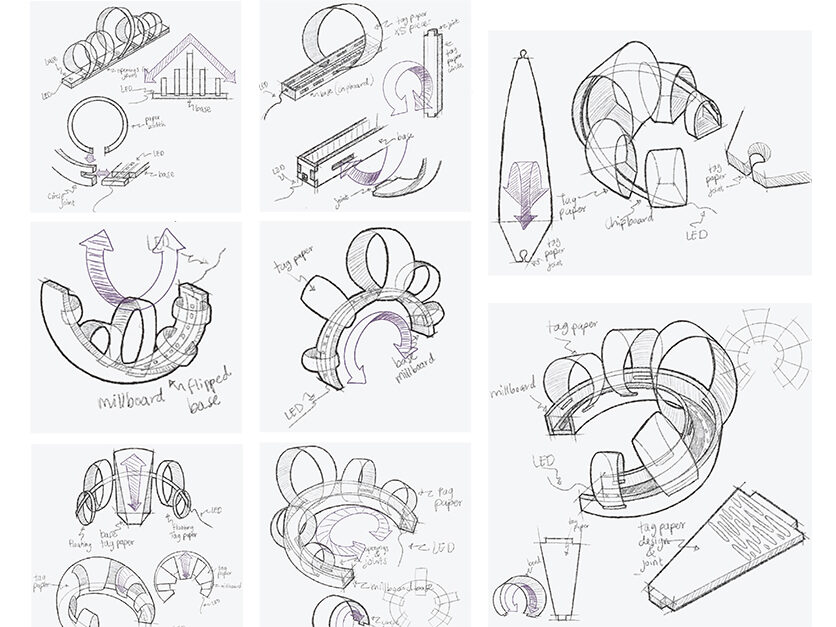

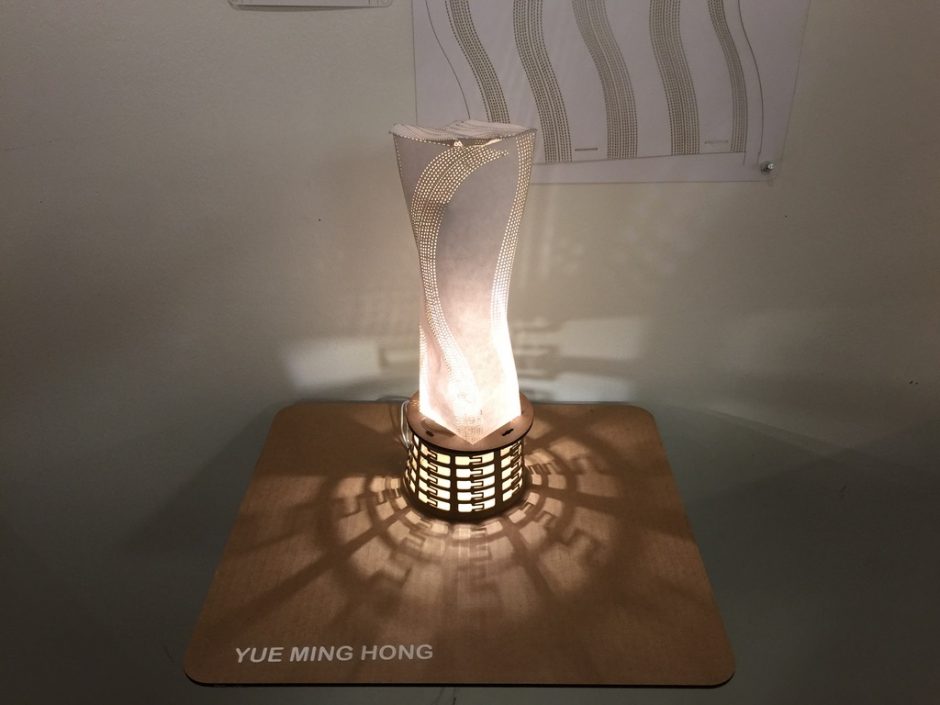

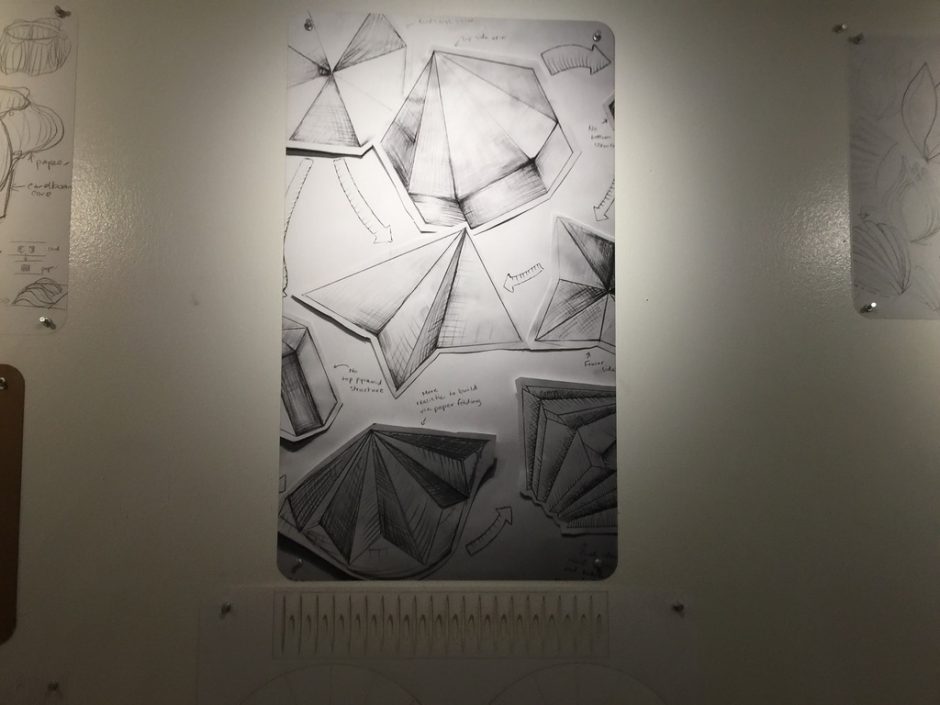

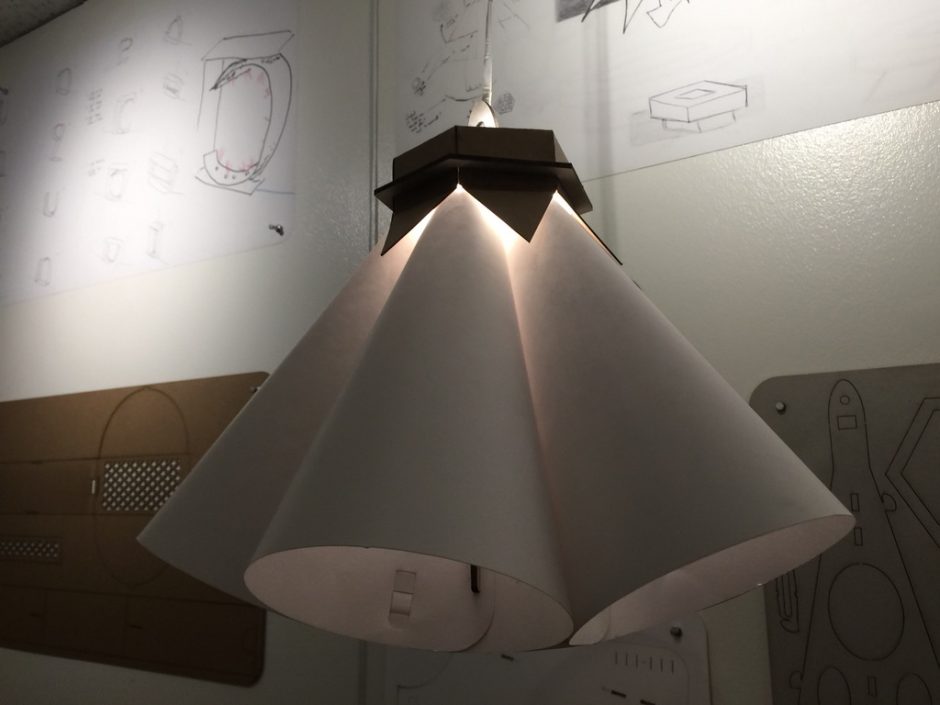

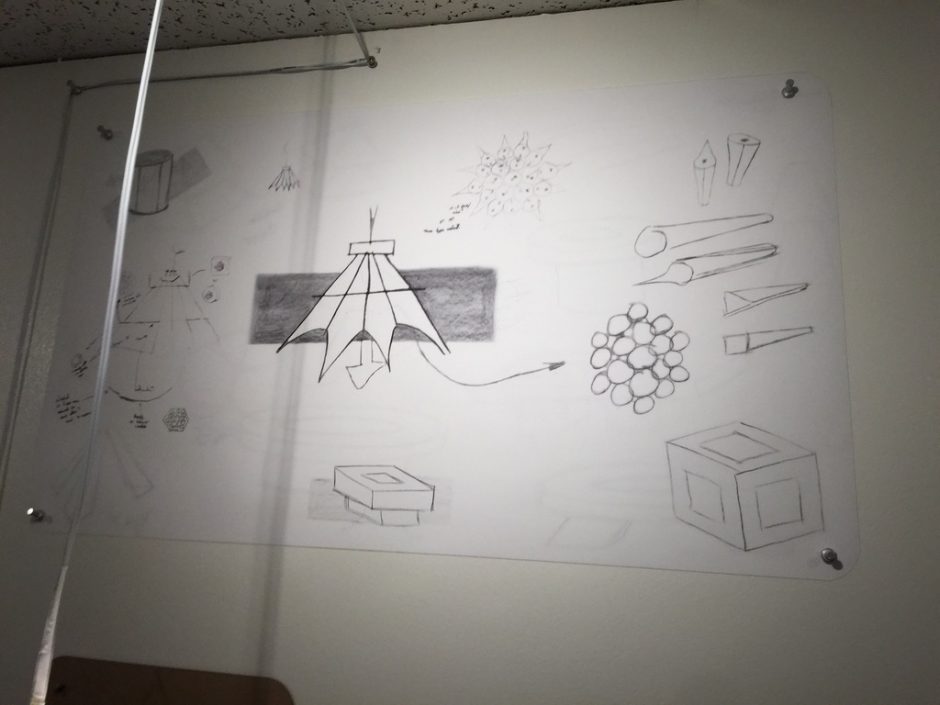

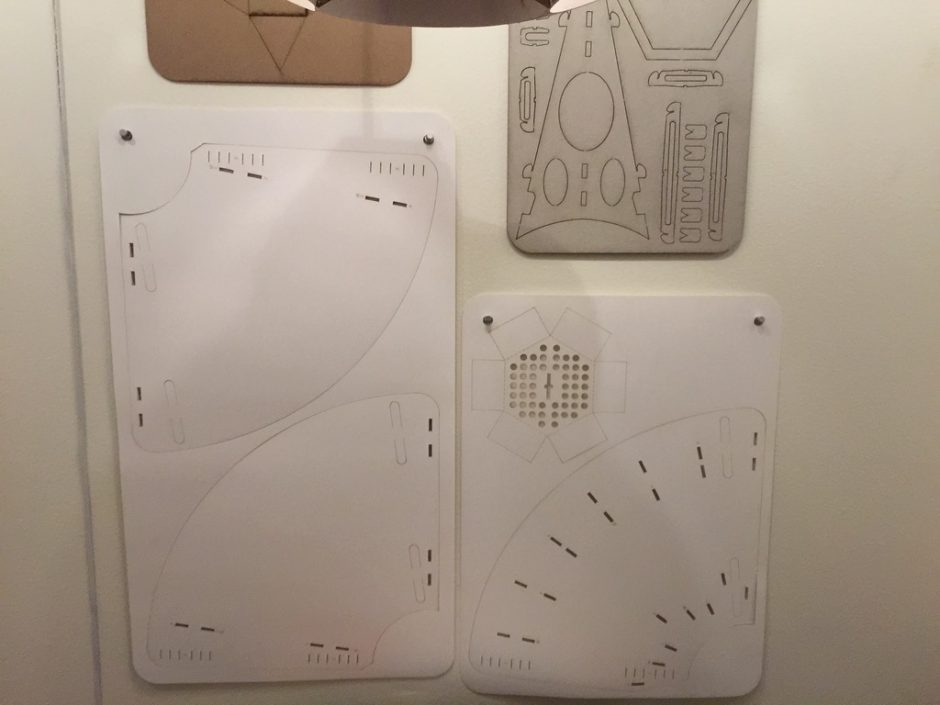

Luminous Object was a Design Formation project this past term. DF instructor Yvan created the project for the students, using only a bare lightbulb as the light source. The students then created prototypes using cardboards and paper. The final lamp was made using plywood, plexiglas and resin. Many of the students used the laser engraver/cutter at the Makerspace to create the parts.

The outcome was a wonderful assortment of lamps, that are all completely different!

See some of the images of the lamp below, and below that are images of the process.

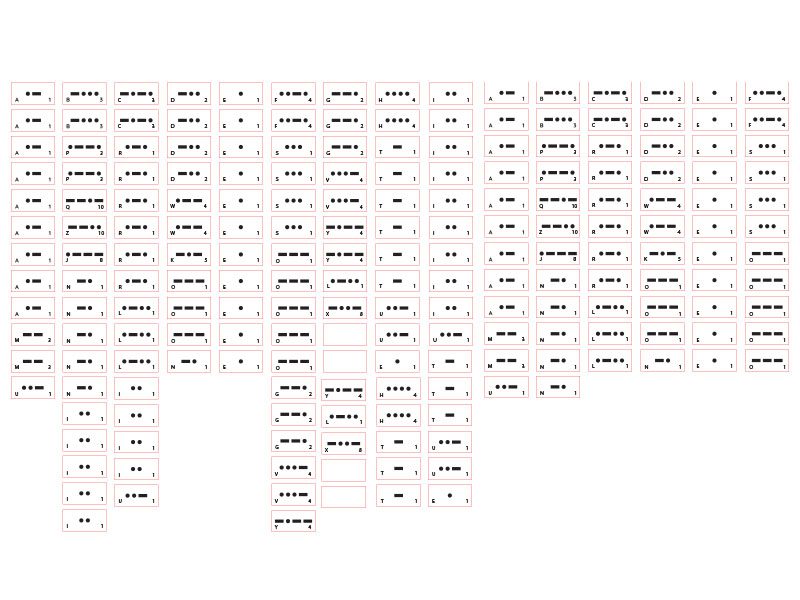

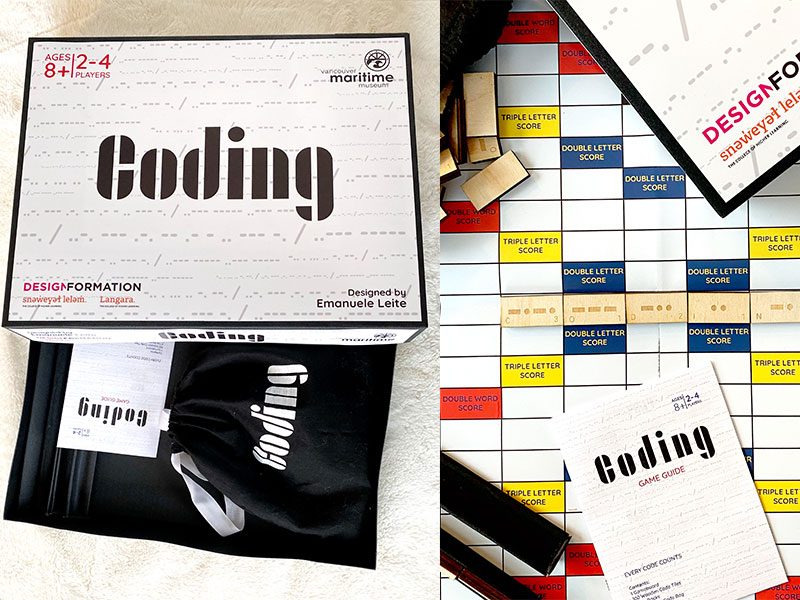

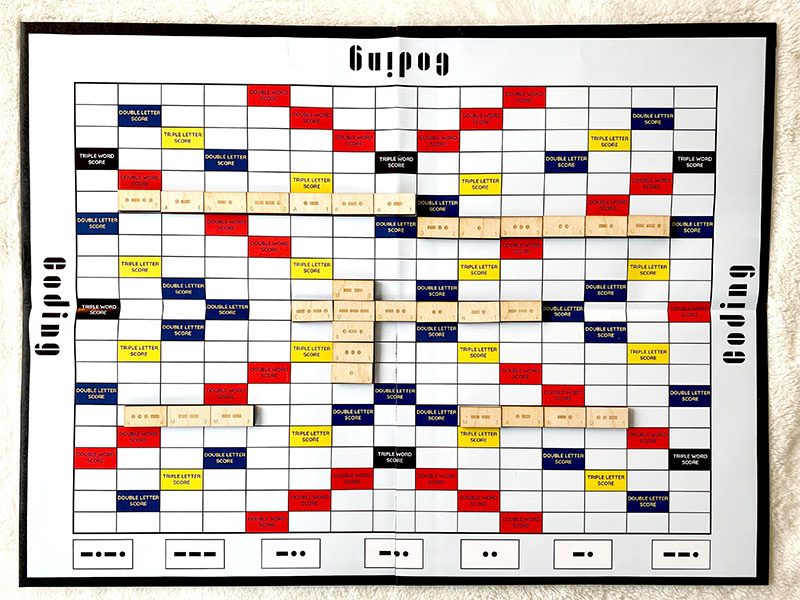

Emanuele Leite’s Morse Code Game Board

Design Formation student Emanuele Leite designed and made a very cool Morse Code game.

Emanuele utilized the Makeraspace to build the game. The game pieces were cut and engraved out of plywood on the Trotec laser. The game box graphics as well as the game board where 2D printed on our large format (44″ wide) Epson Pro 9880.

You can see all the info and details here on the Vancouver Maritime Museum website >

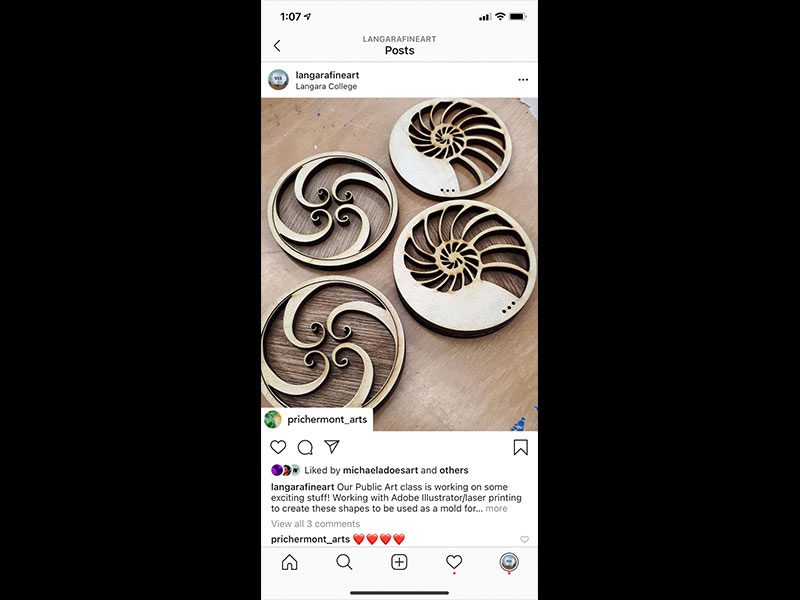

Casting in Bronze from a hand drawing!

This is an amazing process that Fine Arts instructor Devon Knowles has her students doing this semester.

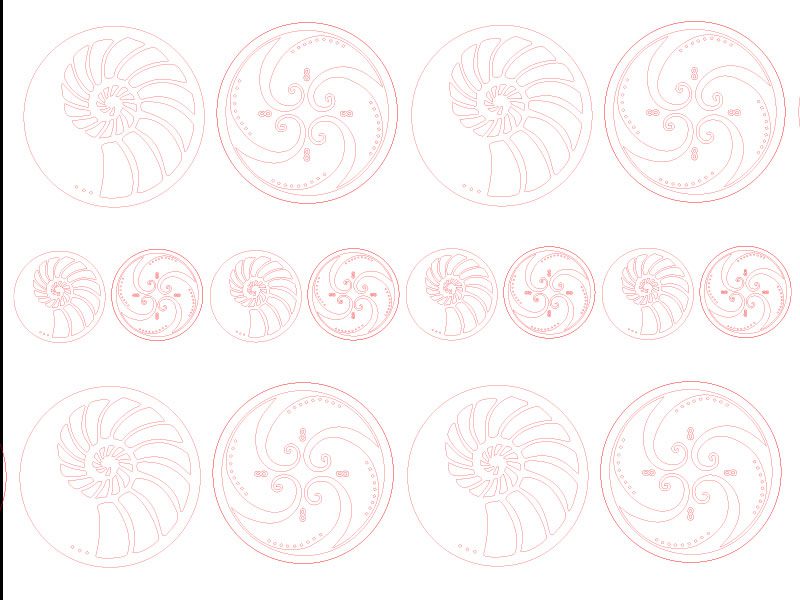

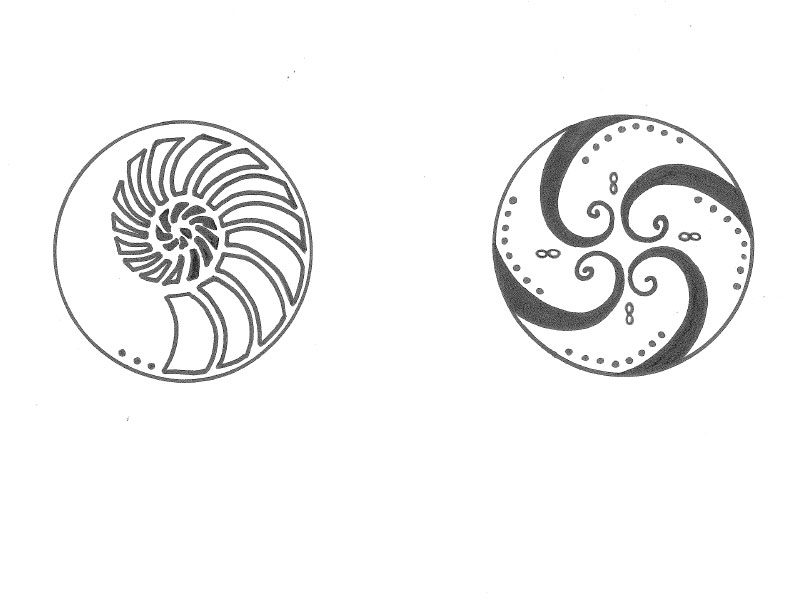

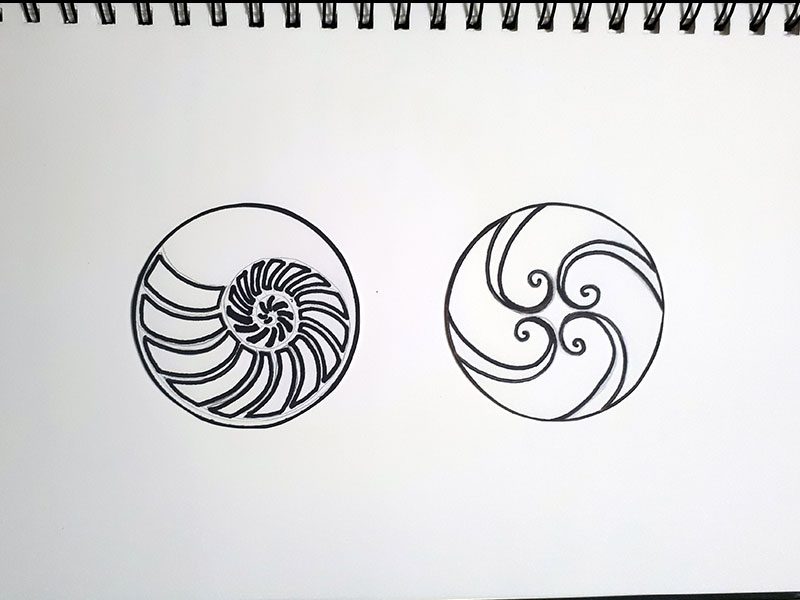

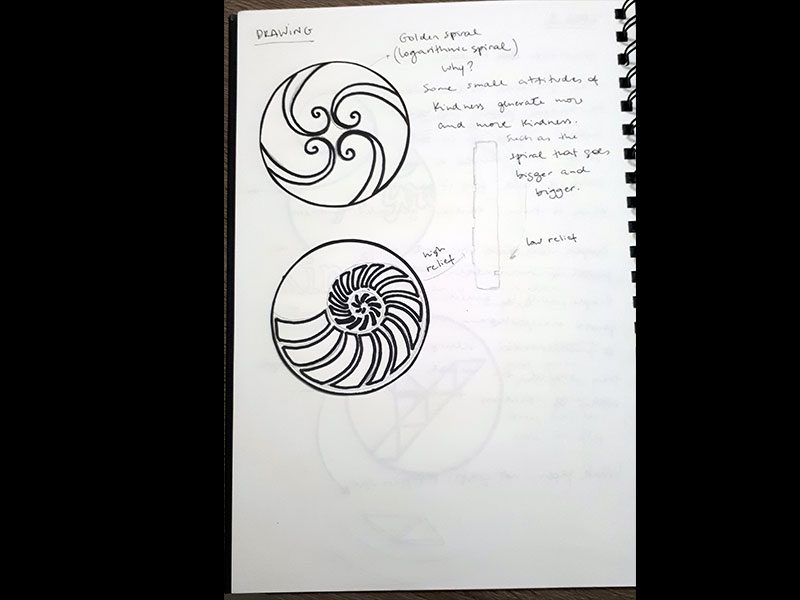

It all starts with a hand drawing, that is scanned on the Langara photocopiers, imported into Adobe Illustrator and traced.

The next step is to prepare the file for the Makerspace Trotec Laser. The lines are the cut out of plywood on the Trotec. The wood pieces are then glued together to form the postive for the sand casting mold. The pieces are then used to make the sand cast and then poured with bronze.

Thank you to Priscila Chermont Daiha Moreira Souza for letting us use and publish her images of the process.

This is the steps of the process:

- Hand drawings

- Watching Maker Space tutorial

- Scanning the drawings

- Vectorizing the drawing/scan in Illustrator for the Trotec

- Trotec laser cutting in 1/8 door skin and 1/4″ and/or 1/2″ plywood

- Laminating the wood components together

- Assessing and preparing object for greensand casting

- Making a green sand mold

- Pouring bronze

- Chasing and finishing bronzes

- Distribution of artwork

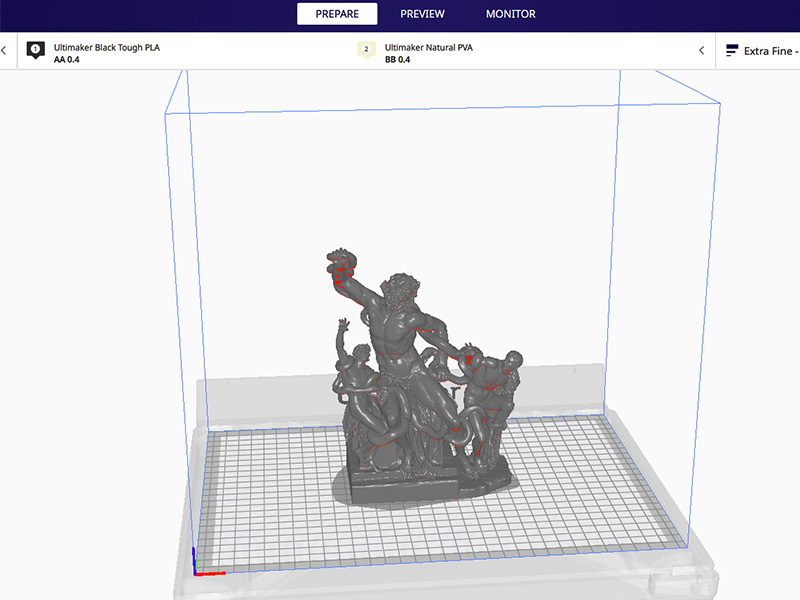

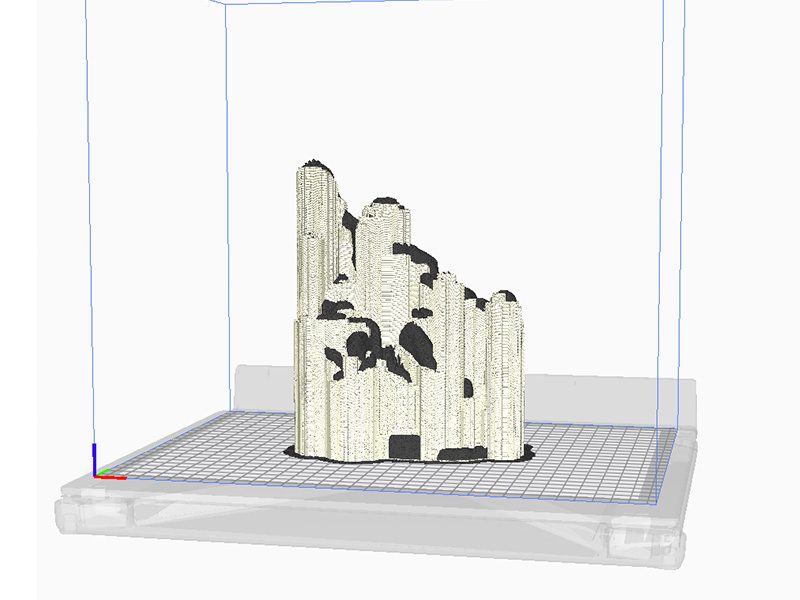

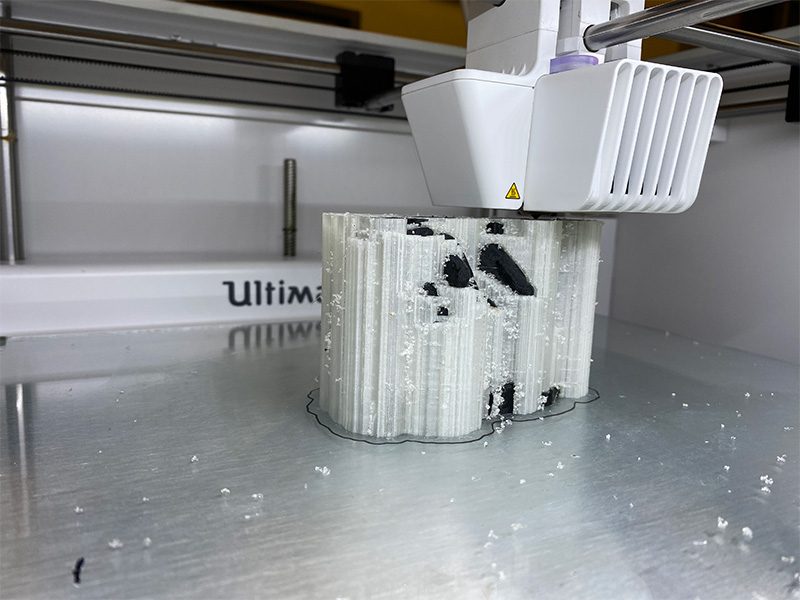

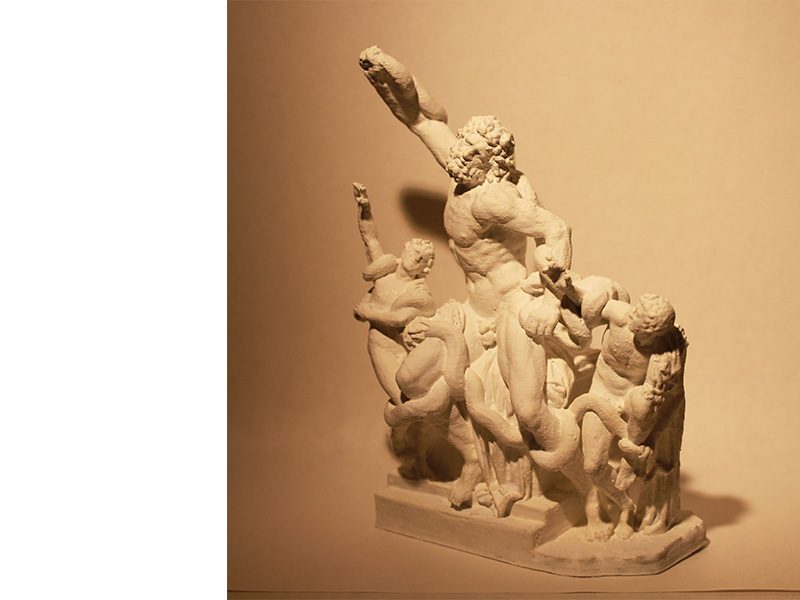

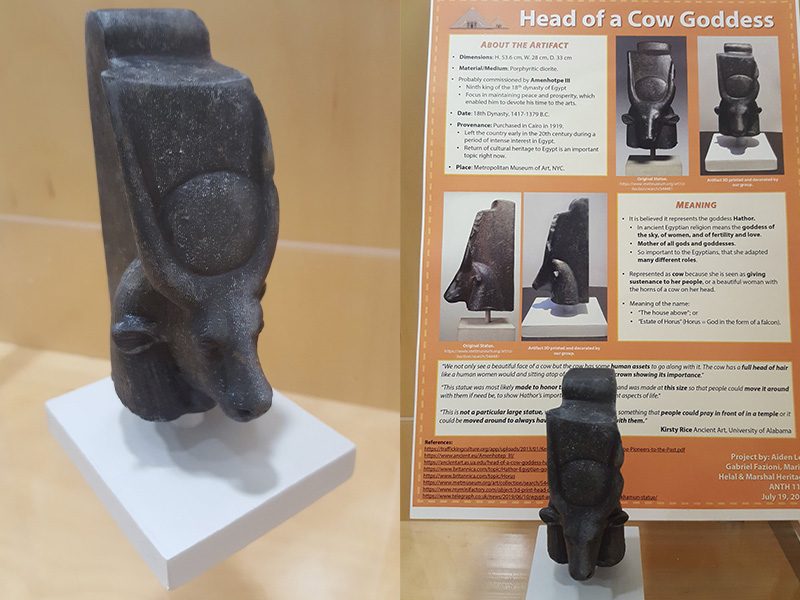

Archaeology Student 3D Print

Cara’s archaeology students 3D print artifacts for one of their projects. We used the Ultimaker S5 to print this, with dissolving PVA supports.

More great prints by the archaeology students in the galleries below.

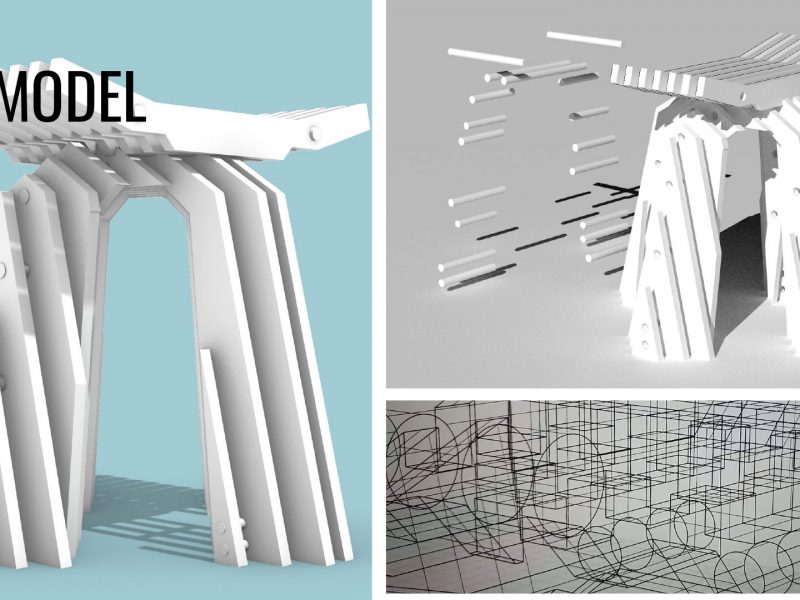

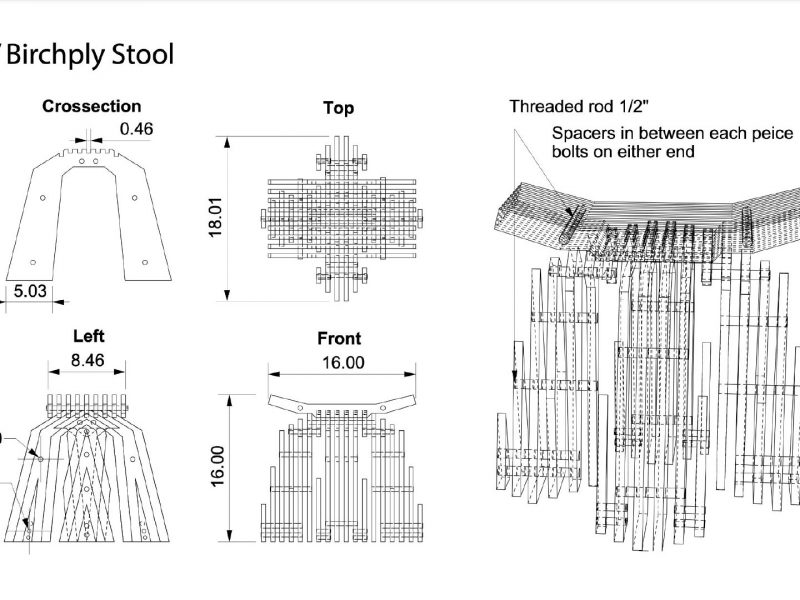

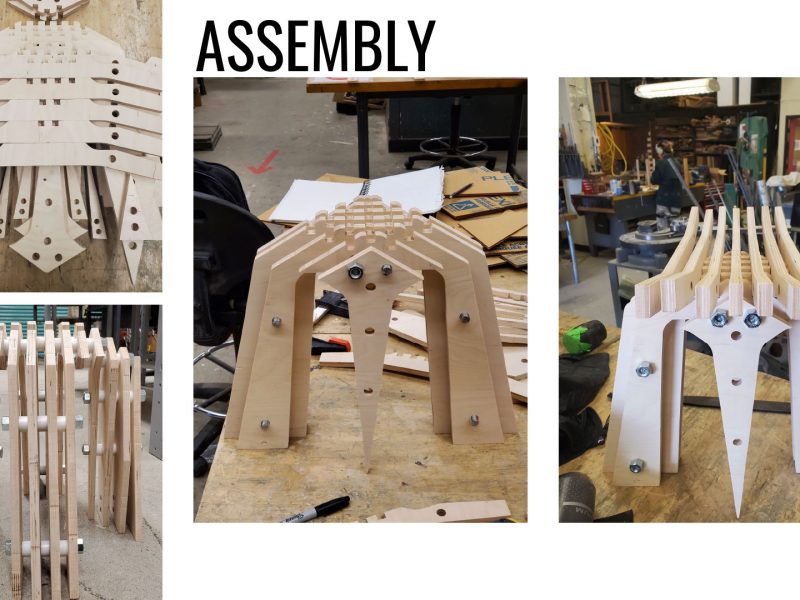

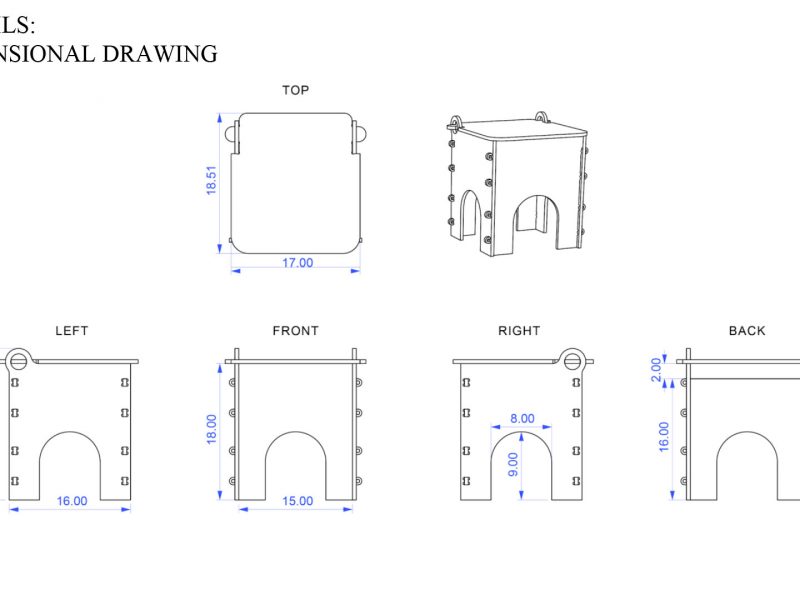

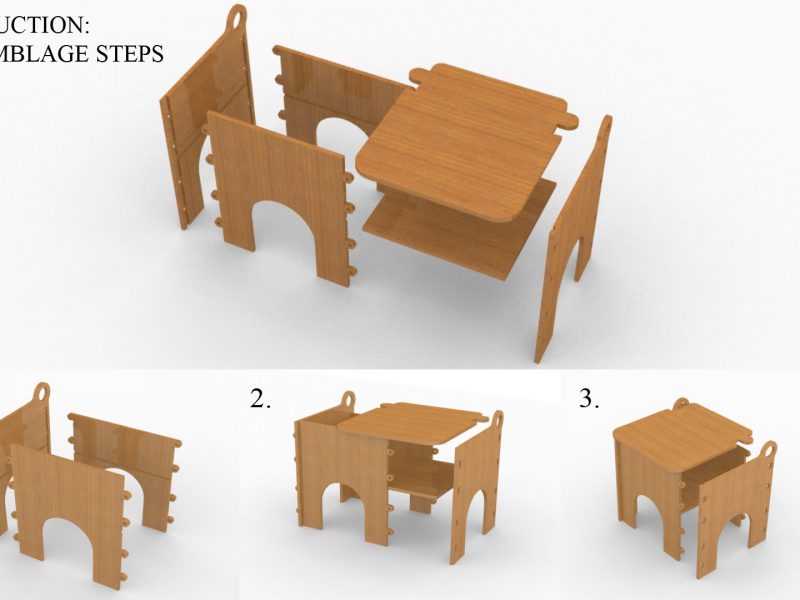

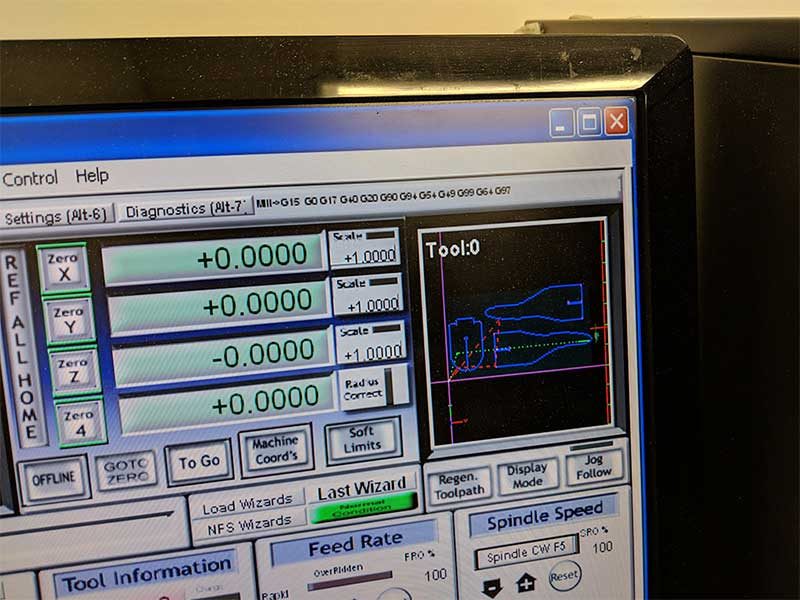

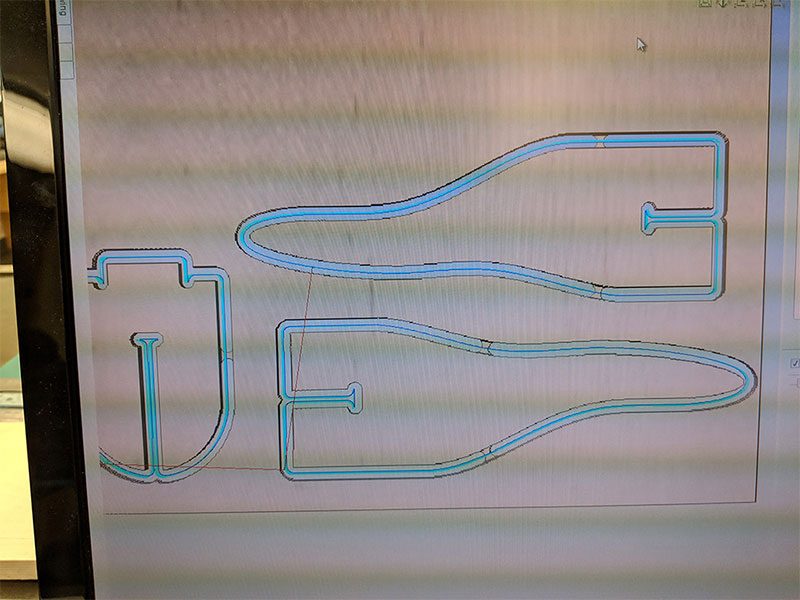

Fine Arts - CNC Stool Project

Philip Robbins Fine Arts Class, where assigned a project to design and build a stool using only the CNC router as the fabrication method and a single piece of 1/2″ birch plywood.

Equipment & Software used:

Prototypes:

– Rhino 3D software

– Illustrator 2D software

– Trotec Speedy 300 laser

Final Version

– Rhino 3D software

– Vcarve Gcode creation

– Mach 3 CNC software

– Romaxx CNC

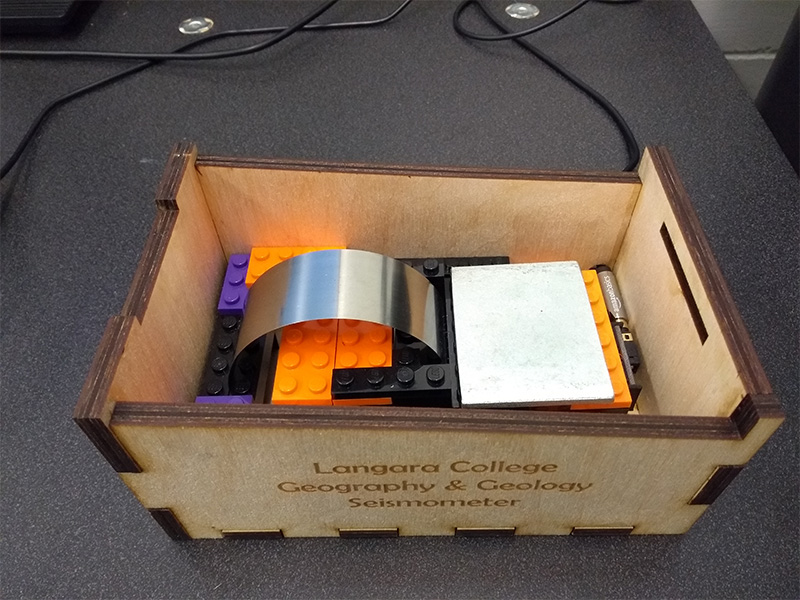

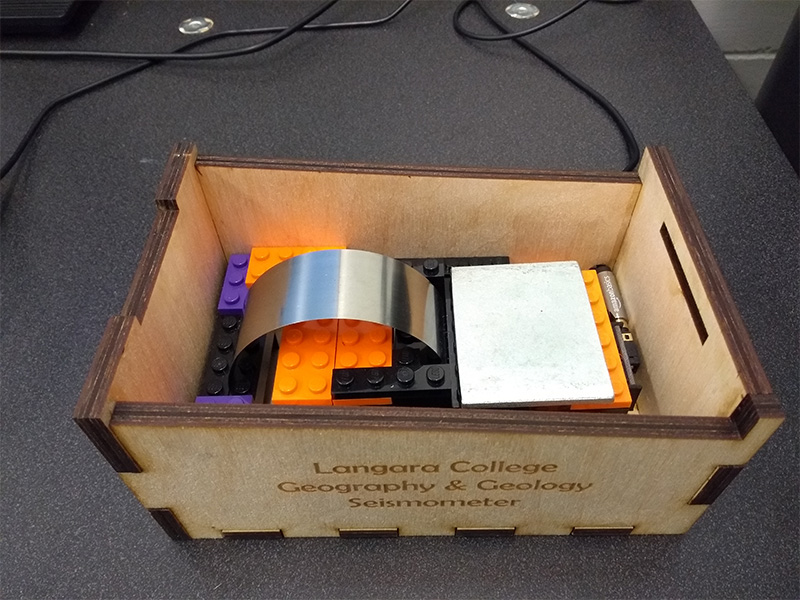

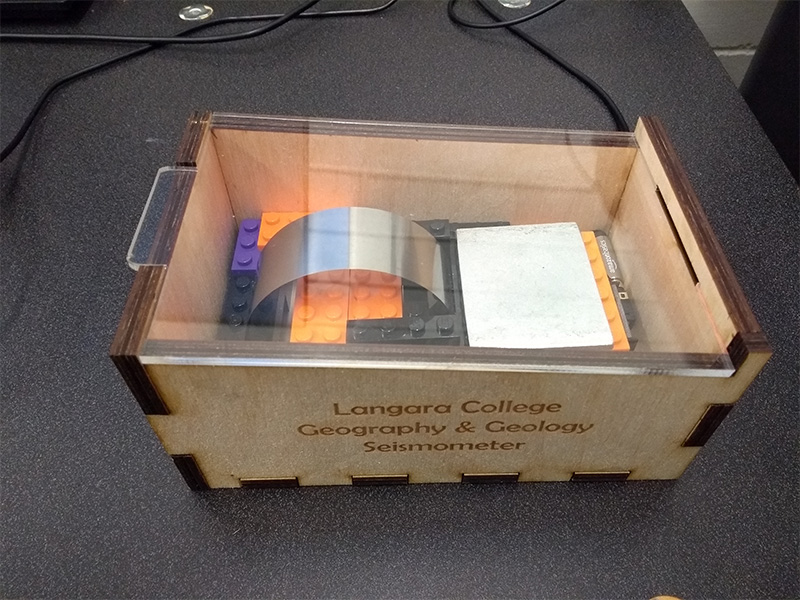

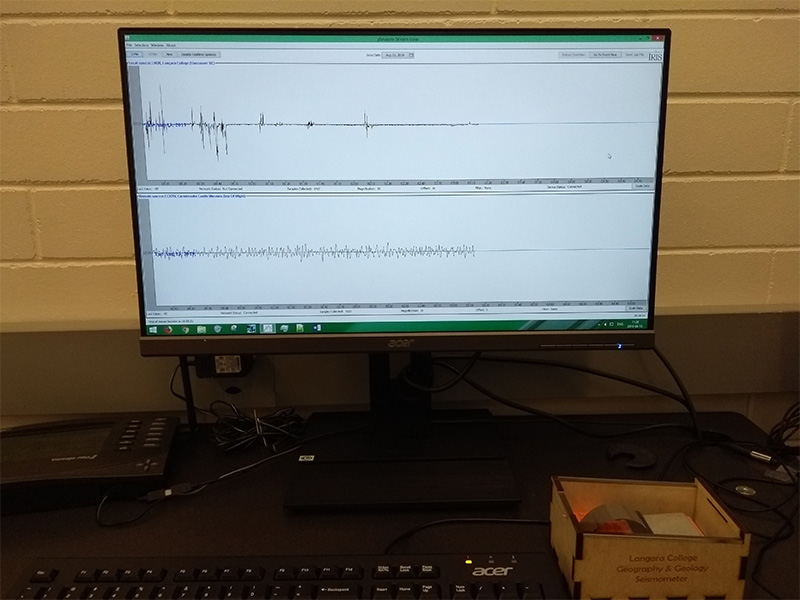

Tony's - Seismometer

Tony, an instructor in the Geography department built this low level seismometer using lego and other parts. He then designed the box and laser cut it at Makerspace.

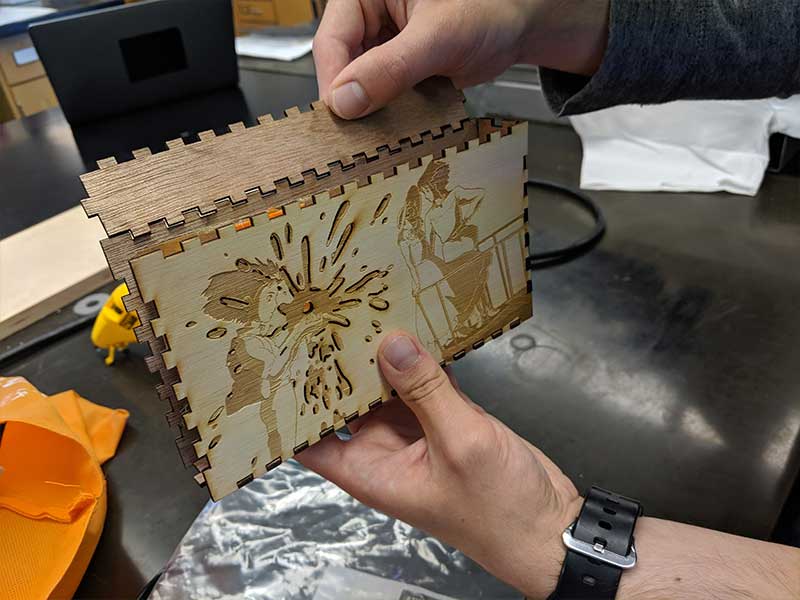

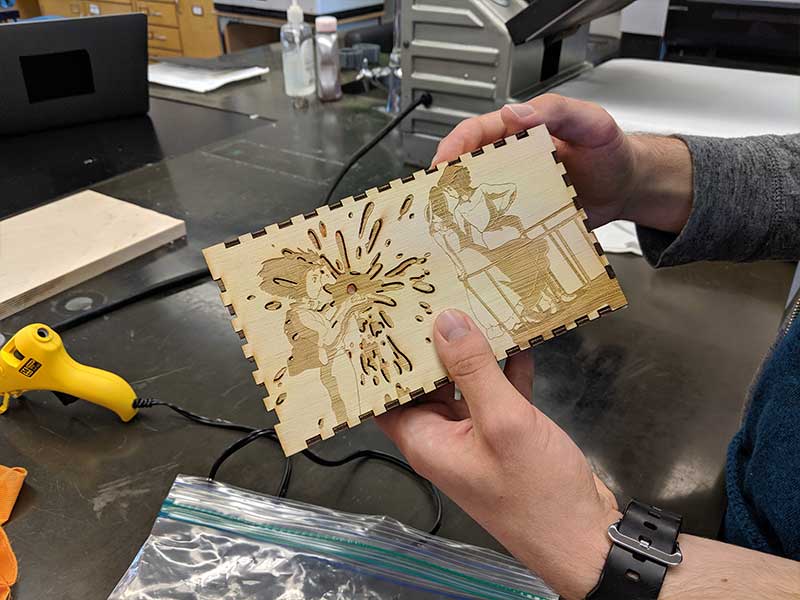

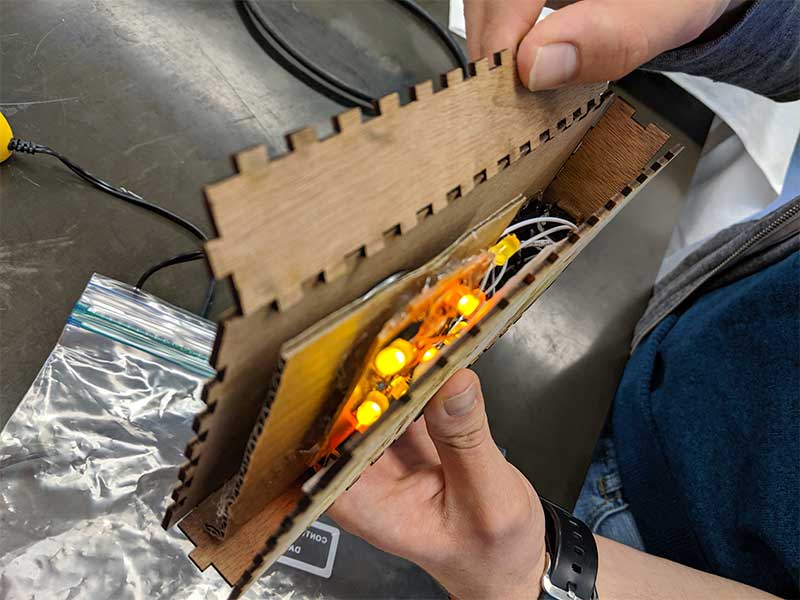

Martin - Music Box

Martin a student at Langara College, created this amazing music box for his girlfriend. It was cut and engraved on the Makerspace Trotec laser. Martin also created the electronics and programming for it. It can play a number of different tunes, and also be loaded with different tunes from the usb port.

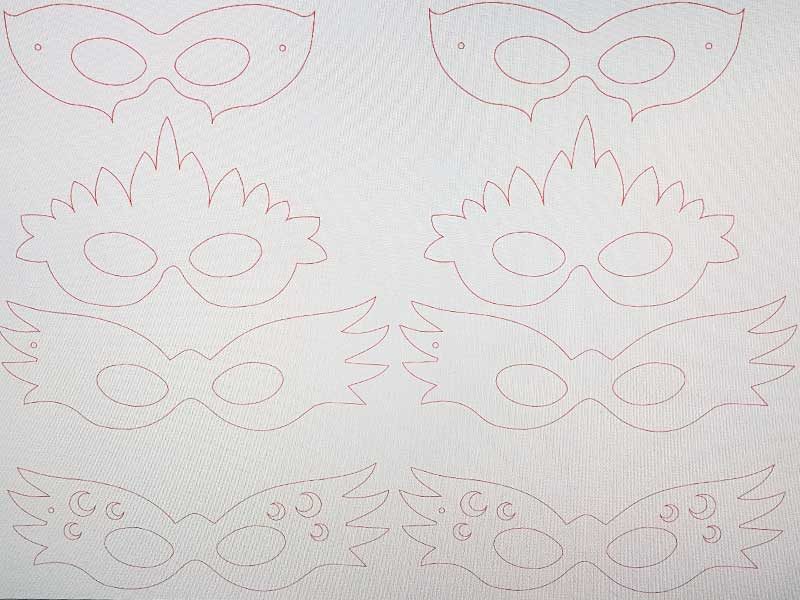

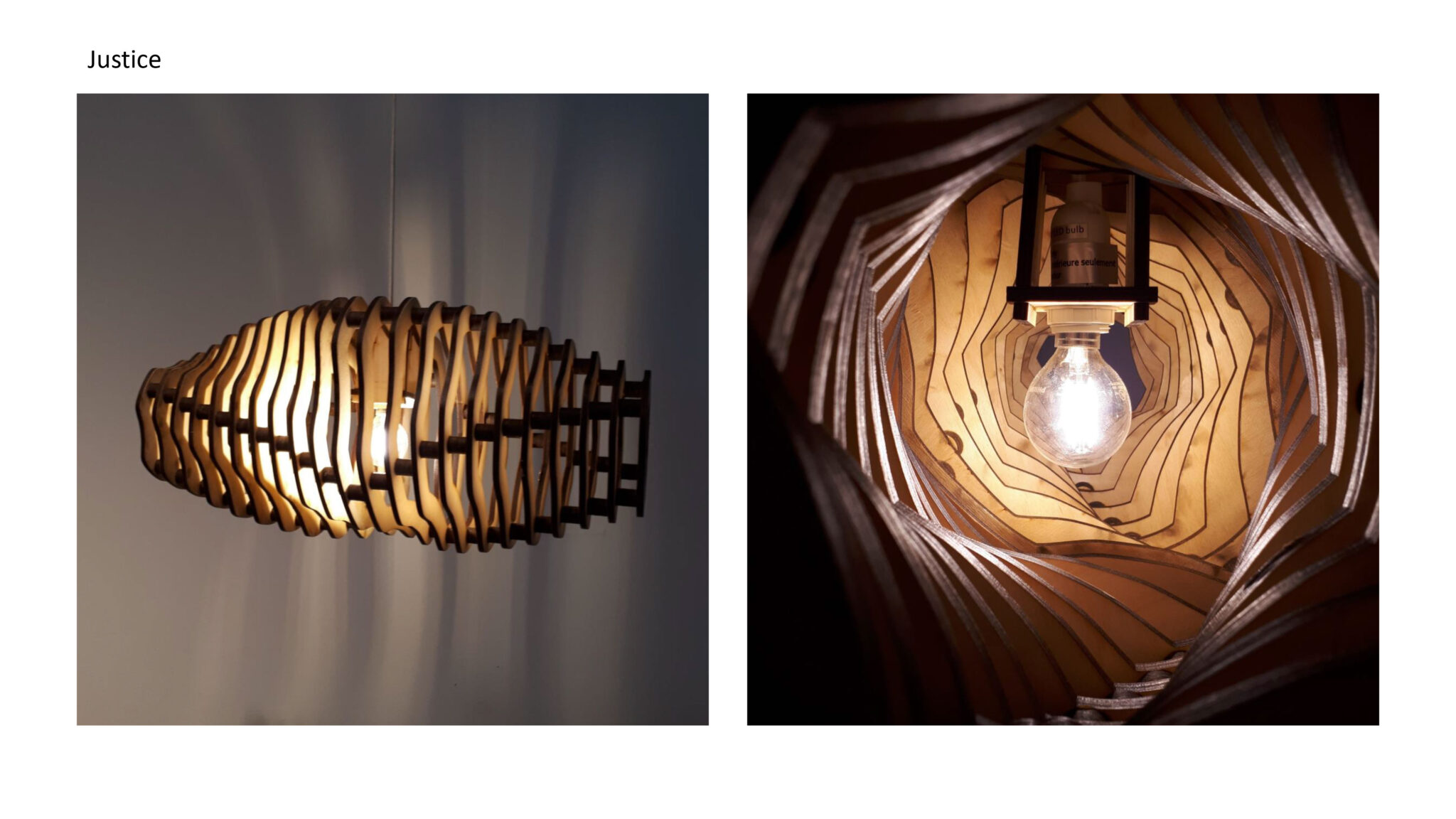

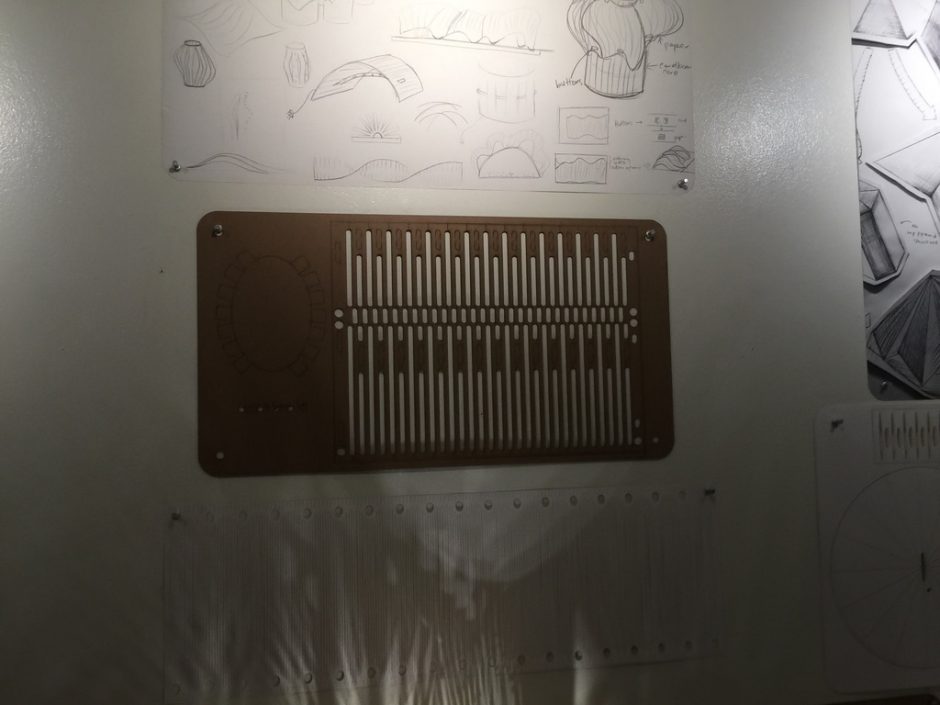

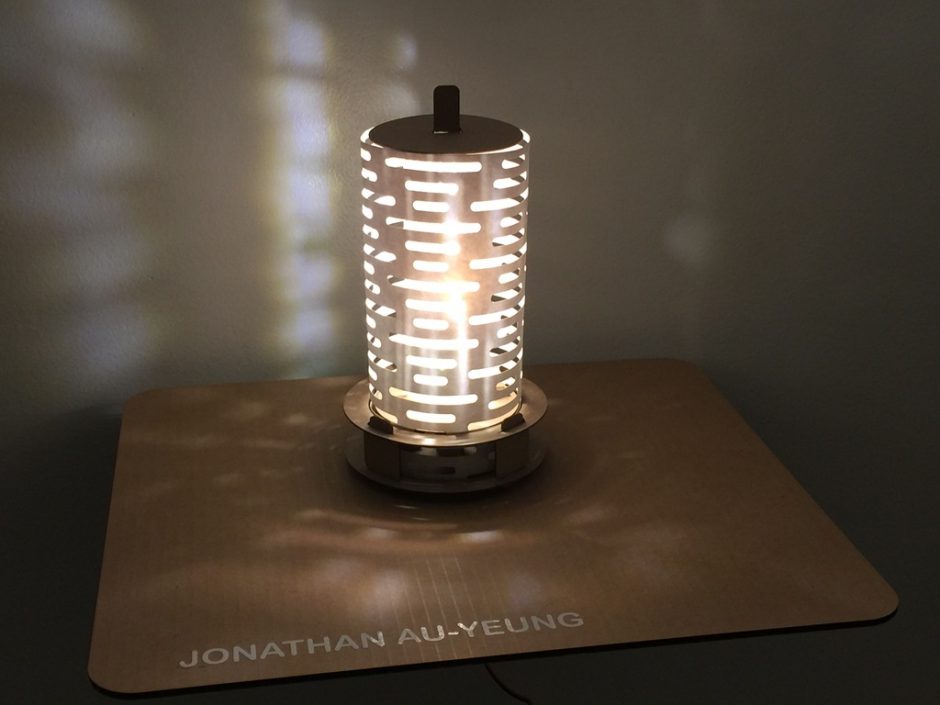

The Illuminati Fine Arts Lamp Project

This Fine Arts assignment was to design an inexpensive lamp out of 100% recyclable/reusable materials, long life and highly efficient low voltage Led strips, and a single manufacturing process (Laser Cutting). The digital design could be shared online as a kit and made cheaply by anyone, or the parts could be shipped flat and assembled easily by the end user with no additional tools needed. All parts can be easily replaced, are completely recyclable and the materials are available worldwide.

![IMG-0338[1]](https://iweb.langara.ca/makerspace/files/2018/11/IMG-03381-940x705.jpg)

![IMG-0341[1]](https://iweb.langara.ca/makerspace/files/2018/11/IMG-03411-940x705.jpg)