Facilities faced a challenge when Neil discovered broken components on windows and doors that were no longer available. This issue was effectively addressed at the Makerspace.

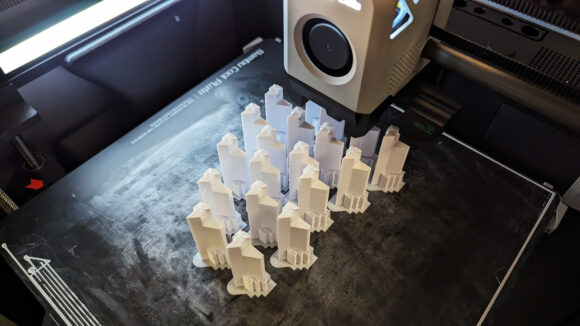

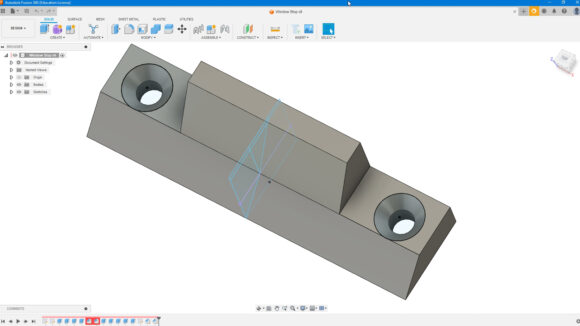

To tackle the first problem, we utilized Fusion 360 for the design of multi-angled stops for the building’s windows. Subsequently, a prototype was crafted using PLA on the Bambu 3D printers. Upon approval, we mass-produced the parts using black nylon on the Ultimaker S5 3D printer.

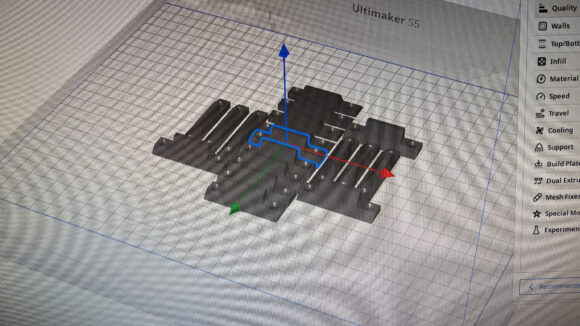

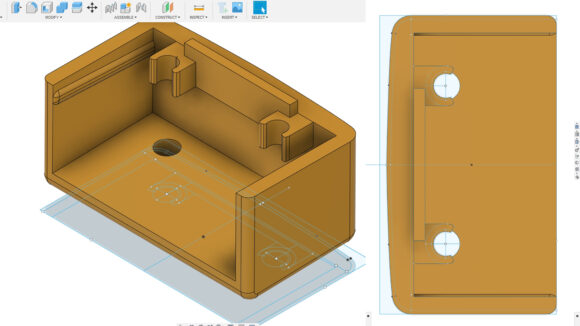

The second issue involved devising end caps for push bars on various doors across the campus. This intricate part, characterized by its absence of straight lines and numerous angles, was also designed in Fusion 360. Following prototyping on the Bambu 3D printers, the end caps were manufactured in bulk using black ABS on the Ultimaker S5 3D printer.

Should you require components for repairs, feel free to visit the Makerspace for a workshop, where we can guide you on solving such challenges. Facilities’ problem found a resolution within the innovative environment of the Makerspace.