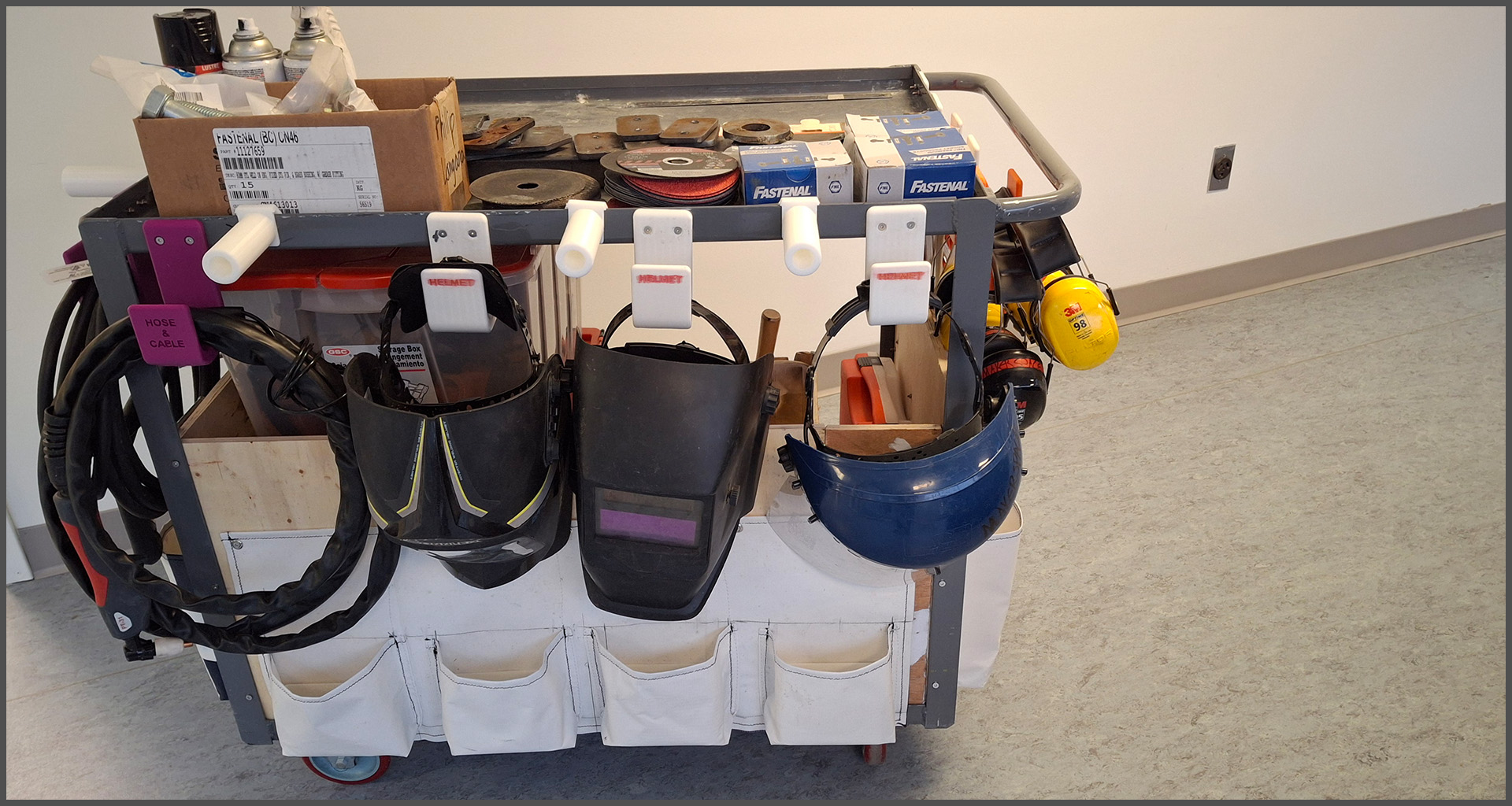

The cart utilized for transporting equipment and tools outdoors during welding or plasma cutting operations required a more efficient and organized setup. To address this, we developed a comprehensive organizational system, leveraging a combination of 3D printing, sewing, and laser cutting technologies to design and fabricate the necessary components.

Below is an overview of the components we created:

- Custom 3D-Printed Hooks: Designed to securely hold various items, including:

- Welding hoses

- Welding helmets

- Extension cords

- Face shields

- Ear protection devices

- Tool Pouches with Reinforced Inserts: Fabricated from upcycled banner vinyl, these pouches were tailored to store larger tools. To enhance durability, 3D-printed inserts were added to the base of each pouch. Tools accommodated include:

- Large clamps

- Electric drills

- Electric grinders

- Upcycled Wooden Toolbox: Constructed from repurposed shipping crate wood, this toolbox was designed to store an assortment of smaller tools.

- 3D-Printed Small Tool Organizer: A compact, custom-designed box created to neatly organize and store smaller tools.

- Upcycled Wooden Panels: These panels were crafted to serve as mounting surfaces for the tool pouches and other components, ensuring a secure and organized arrangement.

- 3D-Printed TPU Bumpers: Made from thermoplastic polyurethane (a flexible rubber-like material), these bumpers were added to the hooks to prevent damage to both the hooks and the equipment they hold.

This system not only improves the functionality and organization of the cart but also incorporates sustainable practices through the use of upcycled materials.