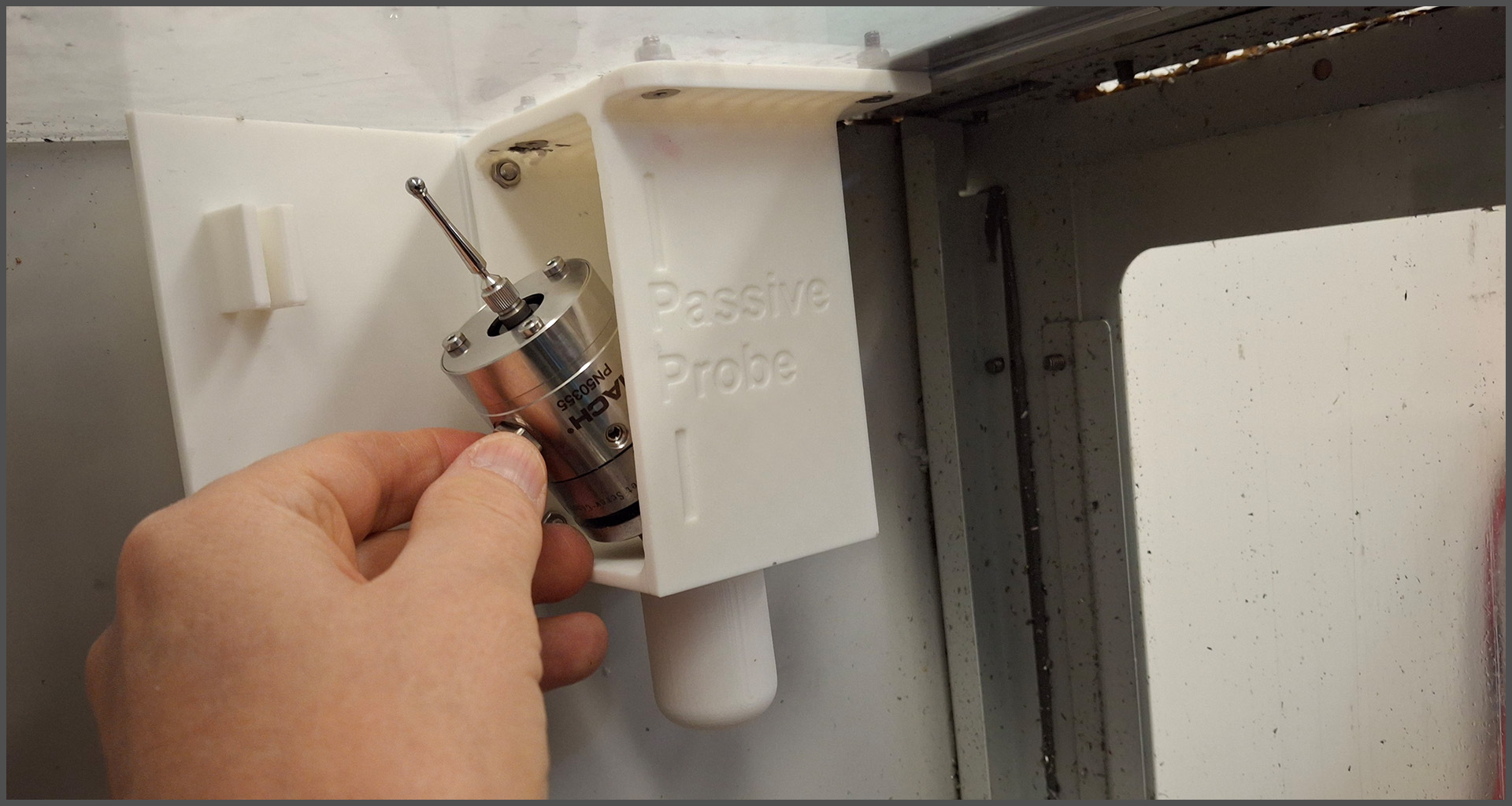

We utilize a Passive Probe with our Tormach 440PCNC mill to accurately determine the G54 coordinates, commonly referred to as the home positions for the X, Y, and Z axes. This probe must be employed at the commencement of each project and whenever the stock material is repositioned, which can occur multiple times during a single operation. Unfortunately, the current setup necessitates that the probe be ejected from the mill head holder and unplugged externally. During this process, the connector is frequently exposed to wet aluminum shavings as it is maneuvered from the machine’s interior to the exterior. Reconnecting the probe requires threading the cord back through the machine, once again subjecting it to the accumulation of shavings.

I have concluded that if the probe could be securely housed within the machine while allowing the cord to remain accessible externally, many of these issues could be mitigated.

Challenges:

- The probe cannot remain inside the housing due to the coolant fluid used to minimize friction on the machine’s cutting tools.

- The presence of metal shavings throughout the machine presents a further complication.

Proposed Solution:

- Develop a water-resistant housing for the probe.

- Install the housing in the upper right rear corner of the machine, an area that experiences minimal coolant spray and shavings.

- Ensure that the connector remains outside the machine, readily accessible for plugging in and protected from shavings.

Find more about this project and other Makerspace Projects here >